Q3 E-commerce Trends to Watch

Q3 E-commerce Trends to Watch

Q3 has ended, and online retailers are seeing a shift in consumer behavior. The main Q3 E-commerce trends to watch include; elongated holiday shopping timelines, social selling, and reduced consumer spending. This post will cover both Q3 e-commerce trends and overarching trends from 2022.

Top Q3 E-commerce Trends to Watch

Consumer Spending Will Change

While we still see strong consumer spending habits, holiday sales are expected to slow. As a result of the economic downturn, holiday sales are projected to grow between 4% and 6%, reaching $1.45 to $1.47 trillion this season compared to an increase of 15.1% during last year’s period, according to a new forecast from Deloitte. With inflation hovering just above 8%, many consumers are making adjustments. According to a recent survey by Bankrate.com and spokesperson Ted Rossman.

“Something has to give. The fact that your rent costs more, your gas, your groceries, there’s a spillover effect to all that.”

Ted Rossman, Bankrate.com

8 of 10 Americans with travel plans are reconsidering or making modifications to save money.

Retailers can expect higher e-commerce sales as customers comparison shop for bargains. E-commerce brands poised for early sales will be in good shape to have a successful Q4.

Holiday Shopping is Coming Early

November typically marks the beginning of Peak holiday sales, but trends show shoppers have already started making gift purchases. According to a Gartner Marketing survey, nearly half of consumers, 48%, plan to shop early for this holiday season, and the big reason is inflation. They are spreading out their spending. Consumers are beginning to scour retail sites for the best deals and promotions, and deep discounts from retailers are expected to be seen early instead of revolving around “Days” or “Weeks” as in years past.

“Consumers will demonstrate less interest in traditional shopping days. Days have become weeks (e.g., Black Friday to Thanksgiving Week, Cyber Monday to Cyber Week, etc.)”

Howard Meitiner, Managing Director, Carl Marks Advisors

Brands that are poised to offer early promotions will be able to capitalize on early sales and offset last-minute delivery complications.

Social Selling is Rising in Popularity and Trust

As a result of COVID-19, consumers found that shopping online could keep them safe and save them money and time. This has increased consumer trust in social commerce. Social commerce is using social media to sell goods or services. From increasing your post frequency to engaging influencers to promote your product, now is the time to double down on social marketing and sales efforts.

Enduring 2022 E-commerce Trends to Watch

Personalization

Consumers are looking for shopping experiences tailored to their preferences. Shoppers are continuing to look for personalization. Personalization includes; displaying recommended products, targeted messaging, and cultivating personalized add-ons. People want their online shopping experience similar to having a personal shopper. AI is powering personalization and getting more accurate by the minute. A brand with a seamless omnichannel experience that offers the best deals and designs for each individual will perform well throughout the end of 2022 and into 2023.

M-Commerce

M-Commerce or mobile commerce will continue to be an e-commerce trend to watch. Mobile purchases are trending to be almost 22% higher than in 2021. It isn’t enough that your site is mobile-friendly; it needs to be optimized for mobile. Consumers are spending more time than ever on their devices. You cannot afford to have a sub-par mobile purchasing experience to capture their attention and their dollars. Here are just a few of the best practices for mobile UX design, according to Toptal.com.

Infographic by Toptal

Chatbots

As AI-powered chatbots become more intelligent, their use in customer service situations is growing. While human connection is still essential in complicated customer service circumstances, a chatbot can more efficiently and effectively share frequently requested information. Furthermore, chatbots are available 24/7, making it feasible to respond to customers instantly, no matter the timezone or time of day. We can expect chatbots in other business areas, including payments, scheduling appointments, and even hiring.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, therefore understanding the roll of Third-Party Logistics is integral to keeping up. In light of this our beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

While Q3 presents a few new e-commerce trends to watch, they are ever-changing. Moreover, from implementing chatbots to longer sales seasons, it can be overwhelming to keep up. However, Falcon Fulfillment specializes in e-commerce fulfillment. Consequently, we can free up headspace by managing every aspect of product fulfillment, from receiving to last-mile delivery.

If you need breathing room to focus on maximizing revenues, core competencies, and flowing with the e-commerce trends, let Falcon help. Talk to one of our agents today.

Let’s Talk!

Grow Your Beer Subscription

Grow Your Beer Subscription

Craft-brew, micro-brew, and larger distillers endured the screeching halt in sales in 2020, courtesy of a global pandemic, and survived because they pivoted their business models. Even though sales were no longer flowing from local bars and restaurants, people were still drinking. Many beer providers launched beer subscriptions and created a direct-to-consumer (D2C) model. This pivot helped existing beer makers fulfill consumer demand without relying on a face-to-face establishment. Even though most of the country is now open for business, beer makers are not only continuing their beer subscriptions but doubling down on them. This article will discuss the benefits of launching a beer subscription, possible complications, and how to grow your beer subscription.

Benefits of Offering a Beer Subscription

Cash Flow Predictability

Cash flow predictability is one of the main reasons to launch a beer subscription. Do not rely solely on the ebbs and flows of sales through distributors, bars, and restaurants. A beer subscription allows your brewery to capitalize on a consistent revenue stream month-over-month. Furthermore, cash flow predictability helps build investment capital to grow the business beyond its current stage.

Higher Margins

Not only does offering a beer subscription provide consistent cash flow, but it also provides higher margins on products than wholesale or retail. Effectively, you cut out the middle man when you offer a DTC beer subscription program. As a brewmaster, you can make more money for the hard work and craftsmanship you put into each bottle. Your customer will thank you as well. More than 84% of craft beer drinkers claim they would like to receive their favorite beverages delivered directly to their homes.

Higher Customer Retention, Lower Acquisition Cost

With a beer subscription, you can personalize the products according to their tastes. Tailor their subscription to their flavors and seasonal preferences. Not only that, but you can build entire engagement communities around your subscribers. From offering private content to marketing contests to win more beer, your customers feel like they are part of the fun. Consumers who jump from being brand aware to becoming brand advocates stick with your company longer than a one-shot-imbiber. In addition to retaining and engaging customers, offering a beer subscription can lower acquisition costs. If you already put in the effort and resources to get someone to sip your suds, it’s a quick transition to offer the ongoing beverage enjoyment. This is particularly easy in the craft-brew industry, where customers pride themselves on experiencing unique brews.

Complications of Beer Subscriptions

Restricted DTC Shipments

As of July 2022, only Ten states and the District of Columbia allowed for DTC beer shipments. A few states allow for a modification in direct-to-consumer shipments. Some states allow consumers to purchase face-to-face in another state and have it shipped directly to them. Another alternative is for a distributor to ship products to a retailer in the consumer’s state of residence for a local pickup. In Montana, residents can purchase a “Beer Connoisseur’s License,” which allows them to have beer shipped directly to their homes. Ironically, wineries have access to nearly 97% of adults aged 21 and older in the US. While DTC beer shipments still face complications, the demand is high, and legislation change is likely.

Compliance Is Complicated

Similar to the restrictions on DTC shipments, other regulations plague the beer subscription model. Remaining compliant when shipping state to state is confusing and often requires the expert knowledge of a regulatory attorney in order to abide by the law. Whether you are orchestrating a home delivery or managing a retailer shipment, violating one aspect of the alcohol legislation could cost you your license and ability to sell in the state. Check out beer distribution laws in your state.

Fulfillment Obstacles

When launching or growing a beer subscription, inventory must be produced, stored, shipped, and allocated with a high degree of intention. Coordinating pick-ups, warehouse receivables, and speedy delivery to maintain product quality becomes tricky. To fulfill the beer subscription model effectively, it typically requires a committed internal employee to manage the intricate details. Additional staffing is needed when your brewery wants to offer a seasonal sale, promotion, or event. Not only must the subscription inventory be protected, but it is also first in line for the special promotion. (Remember, that is how customer retention is maintained.) The need to place beer subscribers’ products in a particular place or staging area increases the need for allocated warehouse space.

5 Ways to Grow Your Beer Subscription

Upsell

One of the easiest ways to grow your beer subscription is to upsell existing subscribers. Offer them more value for more revenue. Whether you offer a slightly higher price point for a few more bottles of liquid craftsmanship or merch, this is the easiest way to increase profits and customer satisfaction.

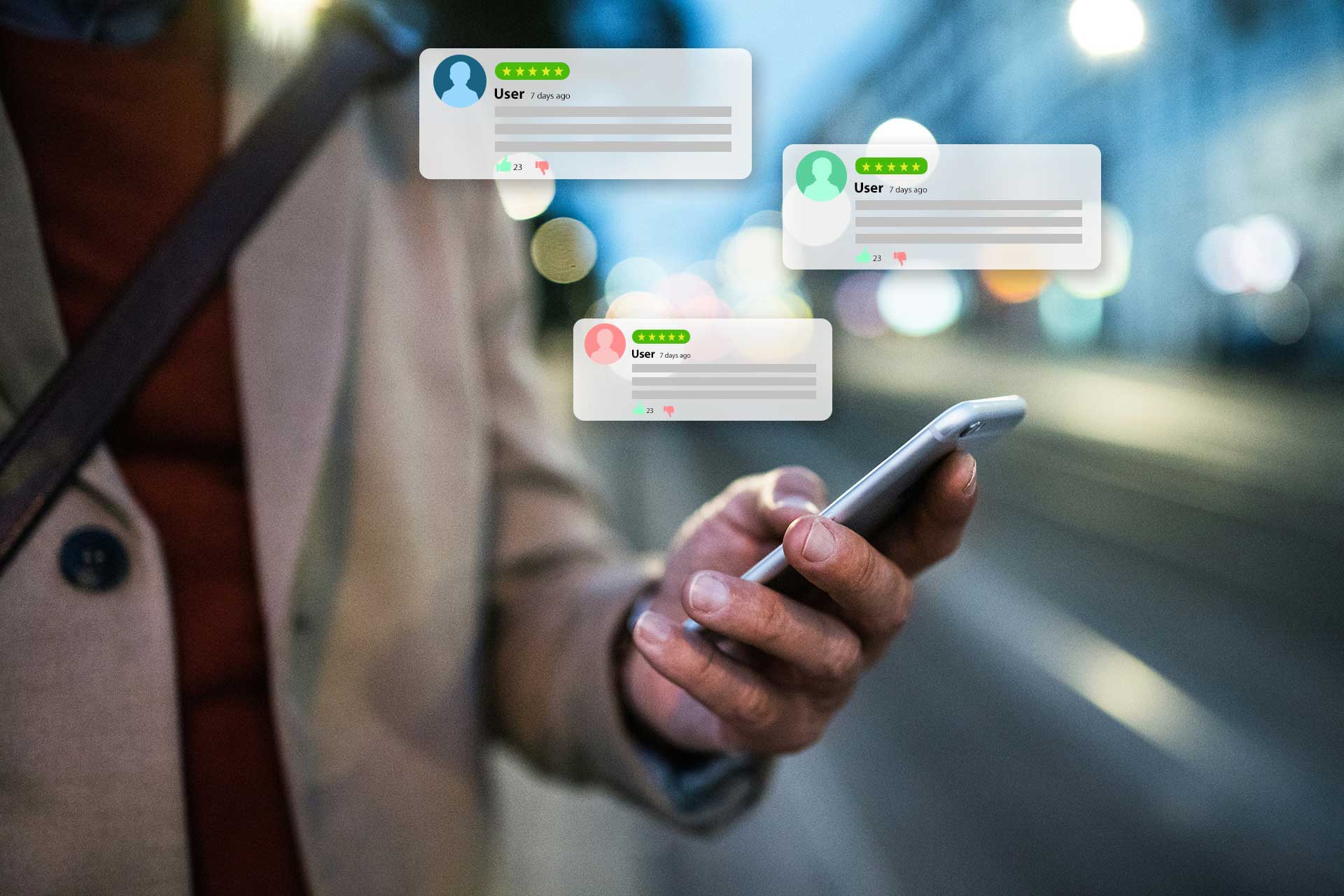

Award Social Proof

The trend across eCommerce that is not going away anytime soon is social selling or social proof. This is the psychological phenomenon whereby people make decisions based on the behaviors and actions of others. Simply put, we buy based on whether or not our friends, social community, or the broader world is doing the same thing. Customer reviews, shares, likes, and tweets are all ways your consumers can help you tap into unexplored territory! Offer customers free tastings, first look, and even trips to the brewery in exchange for sharing their tasting experiences, reviews, and shares of promotions.

Create an Affiliate Model

Similar to the social proof idea, you can offer serious beer subscription advocates a slice of the pie for every new subscriber that uses their link. Most social influencers make a lot of money through affiliate marketing! Any person who is passionate about your beer can become an affiliate and share their love with their friends, family, and followers. The profitabilities are endless when you produce a quality product and award your loyal customers.

Offer Speedy Shipping

The most notable drawback for one of the US’s top beer subscriptions was that it took anywhere from 10-15 days to receive their shipment. That is simply too long for a serious craft-brew snob to wait. Whatever you have to do, make sure that once a customer enrolls for their subscription, they receive their box within 2-3 days tops!

Streamline Beer Fulfillment

Provide your beer subscription customers with a white glove fulfillment experience. A premier fulfillment company can help increase sales and recurring customers by ensuring a branded subscription package is delivered promptly at a price that can beat traditional retail and wholesale margins. Falcon Fulfillment can package and ship your beer subscription with “same-day” efficiency. They also provide inventory management flexibility for irregular seasonal brews, holiday promotions, and new product launches.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, therefore understanding the roll of Third-Party Logistics is integral to keeping up. In light of this our beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

Leveraging a fulfillment company like Falcon can free you up to focus on producing the best darn beer ever and less on managing the logistics of getting the product into the consumer’s hands.

Check out more about Falcon’s beer and wine fulfillment, or talk to one of our agents today.

Let’s Talk!

White Glove Fulfillment - What it is and why you need it

White Glove Fulfillment – What is it?

White glove delivery, fulfillment, and service are common buzzwords in the fulfillment and transportation industry. So what exactly is “white glove fulfillment?” The term white glove finds its roots in the fact that posh English butlers would wear white gloves. White glove offerings are defined as providing meticulous care, attention, or service. When referring to white glove fulfillment, it implies a company or organization provides the highest level of excellence in the logistics industry. From receiving through final delivery, they demonstrates a superior level of attention to every detail. White glove fulfillment is also sometimes called “premiere fulfillment.” in this article, we will outline the minimum standards of a white glove fulfillment company and why you need them.

White Glove Fulfillment – Minimum Expectations

Standard of Excellence in Product Handling

Premium delivery services specialize in products like artwork, furniture, antiques, and fragile items like pottery or china. White glove fulfillment companies provide this same type of attention to detail for every product they fulfill. When a shipment arrives at the distribution warehouse, teams have specific instructions on storing, staging, and prepping the items to deliver when orders are received efficiently. Furthermore, premiere fulfillment teams provide accurate and traceable pick-n-pack services that limit inventory shrinkage and product damage.

Dynamic Problem Solving

Fulfillment provides the network, staff, and resources to ensure products are accurately received, staged, stored for packaging, and shipped quickly as orders fluctuate. Logistics operations are a delicate balance between multiple carriers, manufacturers, and transportation organizations. The entire workflow is negatively impacted if any system piece is non-functioning or even delayed. Partnering with a premiere fulfillment company ensures a higher standard of problem-solving. They will leverage every available resource to iron-out kinks in the workflow. Premiere fulfillment services are game-changing when complications arise, from utilizing a broad network of routes and providers to reconfiguring a warehouse floor to stage products for a last-minute sale.

Expert Branded Packaging and Unboxing Experiences

Nothing will elevate a brand more than a unique unboxing experience. Envision a customer who ordered a cocktail dress. That customer is probably not expecting it to come in a right-size, sustainable package, wrapped with every detail, including a personalized note and detailed garment care instructions. However, when you partner with a white glove fulfillment company, that is the experience your brand can create. Consumers have grown accustomed to the familiar “smile arrow” on every amazon box, so when a new type of box arrives, it holds a bit of mysterious anticipation! That brand is already set apart from the rest. White glove service teams are experts in utilizing unique packaging that will decrease the likelihood of damage and maintain profitability. Simply selecting the right-sized packaging can help boost profitability.

Adept at Temperature Sensitive Product Fulfillment

Not every product can remain stored at room temperature or above. Certain products such as beer, wine, and select beauty items necessitate maintaining specific temperature minimums and maximums to preserve their quality. If you entrust an ordinary fulfillment company with these products, you will likely experience disappointment. There are many fulfillment companies specializing in these types of shipments. However, a white-glove fulfillment often manage these deliveries with as much care and accuracy. The bonus with using a white glove fulfillment team is that they can create a unique opening experience, as mentioned above. When someone opens their favorite micro-brew and receives a complimentary taster of the newest summer shandy, they just might become a brand advocate!

Accurate and Transparent Tracking

Sending accurate product delivery notifications greatly increase customer satisfaction. Consumers aren’t content to wait in limbo about when they will receive their purchases. Top-tier fulfillment teams take pride in ensuring a quick turnaround for delivering orders and precisely tracking the location of a package at any given point in the cycle. Premiere fulfillment companies often leverage dynamic tracking software to provide the most detailed insight on a shipment’s final delivery. This is vital in improving customer satisfaction scores and minimizing missed deliveries.

Premium Customer Service

Endless loops of text-bot customer service platforms cause a higher level of customer dissatisfaction than having a proactive customer response team. Any business owner understands that during moments of customer frustration, it’s crucial not to keep them waiting for answers. A premiere fulfillment company offers the highest standard of communication available to their clients. Whether that is a dedicated account manager or a 24/7 hotline, they have a person standing by to quickly answer your questions and get your business back on track. Not only do they offer a more face-to-face customer service experience, but they also have a polite and professional manner. Like the English butler, a white glove fulfillment team member understands that how they speak is as important as what they say.

Why Your Business Needs White Glove Fulfillment

Any e-commerce company wants to partner with a white glove fulfillment team because it can mean the difference between creating a happy customer and earning a brand advocate. Keeping customers happy is the minimum requirement of any good business. Creating brand advocates should be the goal. How would partnering with a fulfillment team like this help create brand advocates?

Faster Fulfillment and Detailed Delivery Information

Customers expect confirmation emails when they order and when they anticipate the delivery. Now more than ever, consumers want notifications when a delivery is delayed, dispatched, and confirmation of the final drop-off location. The Amazon effect primarily causes this. Not every e-commerce business has the network, purchasing power, and delivery resources of Amazon. Partnering with a white glove fulfillment team can help them provide a similar experience that ensures customer satisfaction without needing the same capital.

Memorable and Shareable Unboxing Experiences

There is something very satisfying about watching someone unbox something. Maybe it is a nod to years of watching people open birthday presents or Christmas gifts that cause us to lean in. Premiere fulfillment teams can help create and deliver TikTok-worthy unboxing experiences. Depending on your brand product and use, you can customize the packaging, opening instructions, and shareable links to capitalize on the unboxing. With other fulfillment teams, you don’t have as much assurance that the product will not include additional marketing collateral or arrive damaged. Creating a memorable and shareable unboxing experience is another way to tip a customer over to a brand advocate.

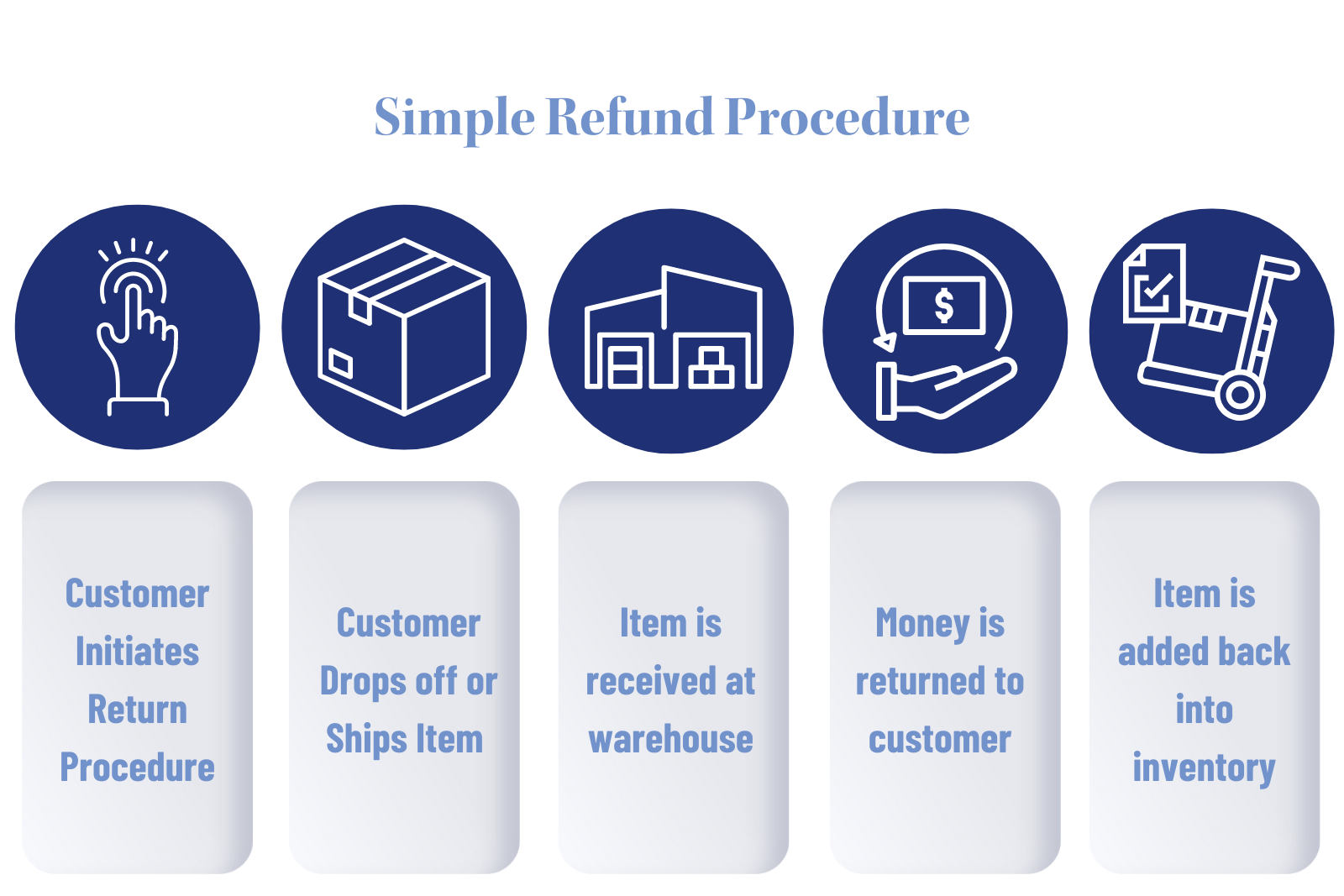

Professional and Polite Returns and Exchange Management

A top-tier fulfillment team can manage the final distribution stages, including returns and exchanges. They manage the entire process of receiving returned goods, inspecting returned items, and accurately restocking and updating inventory. Above and beyond, they provide reports for all returns and can even help modify or update returns policies to protect and increase profitability. In e-commerce’s competitive landscape, your business cannot afford to have a complicated return and exchange policy. That said, if you make it as easy on the consumer as possible, you inadvertently make it more difficult for your business. Partnering with a white glove fulfillment team alleviates the complex and time-consuming returns and exchange management process.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, therefore understanding the roll of Third-Party Logistics is integral to keeping up. In light of this our beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

White glove fulfillment organizations go above and beyond for you and your customers. E-commerce businesses with a premiere fulfillment partner can reclaim precious time and provide the highest level of logistic service without paying “English Butler” money. If you want to learn more about how Falcon Fulfillment can become your white glove fulfillment partner get in touch today.

We would love to help your brand provide your customers with the highest accuracy, attention, and prompt fulfillment.

Let’s Talk!

6 Fulfillment Lessons from 2021

Fulfillment Lessons from 2021

E-commerce hit record numbers in 2020 despite the pandemic. The spike in online shopping continued through 2021, even as the lockdowns loosened. Those businesses that outperformed others were strategic in their investments and partnerships. Fulfillment partnerships were crucial in sifting the success stories. Here are a six fulfillment lessons from 2021.

#1 Diversification is Critical

The supply chain backlog will continue to be an issue through 2022 based on lockdowns and shortages coming out of Asia. The most successful e-commerce brands diversified their logistics plans by expanding relationships with suppliers, vendors, import/export partners, and fulfillment companies. Businesses can no longer have solitary partnerships within their logistics framework.

Manufacturing

Sourcing multiple manufacturing partners will be a strategy to continue to explore and employ during 2022-2023. Parts and products were hard to source in 2021. The main issues were the lack of products exported from Asia, which caused many e-commerce businesses to turn to domestic providers. Look for multiple manufacturing partners, both global and local. This can help hedge unforeseen delays, tariffs, or political regime shifts that might halt production.

Fulfillment Partners

In addition to manufacturing, expanding fulfillment partnerships is another key to maximizing sales and minimizing delays. Choose a fulfillment partner that has multiple distribution centers. Multi-site fulfillment partners will be the most effective as they provide an additional layer of diversification. The best fulfillment partners will also have working and healthy relationships with other logistics-related organizations. E.g., Suppliers, shipping carriers, and shipping supply manufacturers.

Technology

Lastly, it was a massive year for technology. When tech works, it’s fantastic; when it crashes, it is devastating. e-commerce companies that had tested and tried their technology and expanded their tech investment rose to the top of the food chain. The global pandemic brought a massive need for technology infrastructure for fulfillment and logistics. Some key areas where tech made all the difference were inventory management and real-time transportation tracking.

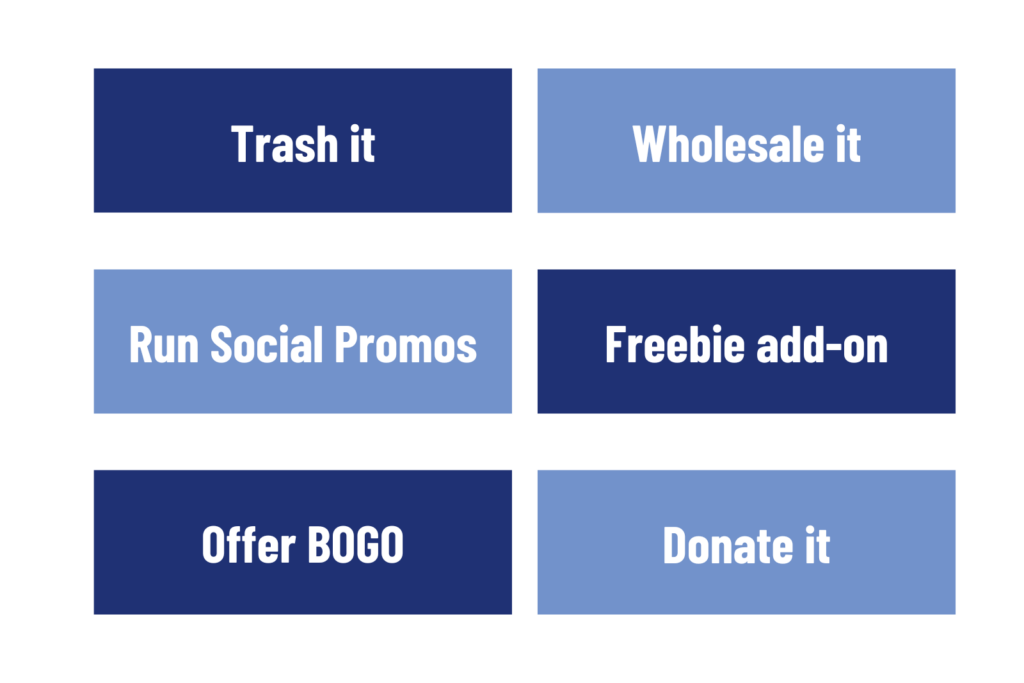

#2 Offload Inventory

If 2021 didn’t bring massive sales of specific SKUs, it is time to liquidate those assets. Besides paying for unnecessary storage, having slow-moving or dead stock is also a symptom of overbuying or poor forecasting. Revisit your inventory management tools and determine what products are moving and are projected to continue to do well. Then off-load product that is no longer moving. One of the best benefits of using an automated inventory management system is accessing perpetual tracking. Leveraging this kind of technology can help strategically run marketing campaigns like BOGO when slow-moving stock needs to make way for higher-selling products. Some ideas to help with liquidating inventory include:

If 2021 didn’t bring massive sales of specific SKUs, it is time to liquidate those assets. Besides paying for unnecessary storage, having slow-moving or dead stock is also a symptom of overbuying or poor forecasting. Revisit your inventory management tools and determine what products are moving and are projected to continue to do well. Then off-load product that is no longer moving. One of the best benefits of using an automated inventory management system is accessing perpetual tracking. Leveraging this kind of technology can help strategically run marketing campaigns like BOGO when slow-moving stock needs to make way for higher-selling products. Some ideas to help with liquidating inventory include:

#3 Automate Customer Service Communications

The post-pandemic consumer expects a higher level of communication. Confirmation and tracking emails to consumers have a 60% open rate. E-commerce customers want to know their order was processed, when to expect it, and if any delays occur. Ensure that your fulfillment communication strategy is as automated as possible. From confirmed order, to final delivery and satisfaction surveys, everything should be as seamless as possible. Invest in building out workflows that alleviate customer support tickets.

#4 Build Out Longer Timelines

One fulfillment lesson from 2021 that stands above the rest is the likelihood for delays. From manufacturing to supply chain, delays were one of the single greatest problems and frustrations for e-commerce businesses. Those companies that rose to the top had contingency plans that built out longer timelines. They preemptively ordered parts and components before they actually needed them. Furthermore, they extended delivery times when they knew it wasn’t likely they would meet the 2-day shipping expectation. Building out a longer timeline will help hedge unavoidable lags in receiving, production, and final delivery.

#5 Social Proof Sells

No matter what type of e-commerce you run, social proof selling is here to stay. More than ever before consumers are consulting reviews, star ratings, and social media popularity that a brand has before making a purchase. This idea will continue to grow and become more immersive, especially as e-commerce and the metaverse converge.

No matter what type of e-commerce you run, social proof selling is here to stay. More than ever before consumers are consulting reviews, star ratings, and social media popularity that a brand has before making a purchase. This idea will continue to grow and become more immersive, especially as e-commerce and the metaverse converge.

#6 Adapt for Continued Supply Chain Issues

The supply chain is slowly recovering but it is not in a place of strength. e-commerce has to be prepared to pivot at any moment in order to accommodate for ongoing supply weaknesses. Take into consideration the entire fulfillment journey. Falcon Fulfillment provides a full supply chain management suite. However, if you choose to manage your supply chain in-house or with another fulfillment partner ensure they can manage flexible shipment handling from your manufacturer as well as streamlined delivery logistics. These two components allow you to receive products in varying packaging and provide end-to-end communications on orders.

Understanding Inventory Shrinkage in Retail

Inventory shrinkage, often due to theft, errors, or damage, can lead to significant losses for retailers. In this guide, we’ll discuss strategies to prevent “inventory shrinkage in retail” and how 3PL and fulfillment services can play a vital role.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, therefore understanding the roll of Third-Party Logistics is integral to keeping up. In light of this our beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

We learned a lot of fulfillment lessons from 2021. The insights and strategies employed by the most successful e-commerce businesses are crucial in 2022 and beyond. Diversifying everything from manufacturing to technology helped companies overcome demand and delays. Offloading inventory, automating communications, and leveraging social proofing improved the bottom line. Lastly, building out longer fulfillment timelines and being prepared for continued supply chain weaknesses will separate the prosperous from the pitiful in 2022. Falcon Fulfillment can help implement all of these lessons.

We are a people-first business that succeeds when our customers succeed. Get in touch with one of our agents today.

Let’s Talk!

9 Ways to Prepare for Peak Season Fulfillment

9 Ways to Prepare for Peak Season Fulfillment

It’s July, so why are we already discussing ways to prepare for peak season fulfillment? Because now is the time to start planning. The e-commerce peak retail season begins in October and runs through early January. Summer is the time to review your fulfillment process, inventory management, forecasts, and data to make informed decisions. E-commerce sales dramatically increased during the COVID-19 pandemic and haven’t slowed much. To prepare for peak season fulfillment in 2024, we need to start now. Planning Christmas in July will set your e-commerce apart when the tidal wave of purchases starts. Here are nine ways to prepare for peak season fulfillment.

#1 Create Data-driven Demand Forecasts

It is crucial to review the most recent data you have regarding projected peak inventory demand. Delve into the data from the most recent peak season and quarter-over-quarter sales fluctuations. Dissecting the data is the best way to forecast accurately. Data points to focus on:

Digging into the data is the most tedious and critical task when preparing for peak. E-commerce businesses typically have multiple systems collating their data. If you partner with a 3PL like Falcon Fulfillment, they can provide a baseline report for fulfillment-focused data. Start now so that you won’t be scrambling to capitalize on consumer spending by the time peak season begins.

#2 Prepare Inventory

Based on your forecasting, begin to work with suppliers and manufacturers on projected sales during peak season. This helps to mitigate stockouts, backorders, and losing customers. The more information you can provide to your partners, the more likely you will have a triumphant peak. Pre-order stock where possible and negotiate with warehousing suppliers. This will help circumvent supply chain issues. Ensure you have accurate reporting for inventory levels. Several benefits of using an inventory management system include; accurate tracking, limiting human error, and full inventory transparency. Now is the time to implement new inventory management software and test for accuracy.

#3 Utilize Distributed Inventory

To prepare for peak season, start leveraging multisite distribution. If you are fulfilling in-house, partner with a 3PL that can add multiple fulfillment centers. Leveraging distributed inventory enables you to offer lower shipping costs and increase conversions. E-commerce businesses can take advantage of 2-day, expedited, and free shipping with a minimum spend threshold. This can increase your average order value and reduce cart abandonment.

#4 Streamline Internal Communications

Successful fulfillment relies heavily on clear, transparent, and consistent communication. This is never more true than during peak when it can be exponentially difficult to get help or responses from fulfillment teams. Start now by reaching out to suppliers, manufacturers, 3PL partners, and other distributors that can make or break your peak season sales. Determine what worked well in past years and highlight problem areas. Set protocols in place now for who will be handling what aspects of the fulfillment process. Inform in-house teams of these plans as well as vendors and suppliers. Ensure that your e-commerce staff knows who to contact when situations arise. Have discussions with marketing and sales teams to review inventory levels regularly. This will improve efforts to push “in-stock” products and reduce “out-of-stock” disappointments.

#5 Automate Customer Communications

Communication is vital in establishing expectations for your consumers. Automate every aspect of customer correspondence that you can. When you have more orders than you know what to do with is not the time you want to have to send out 5000 individual delivery delay emails. Invest in email automation that can inform customers when key trigger events occur. Some examples are; processing delays, shipping and tracking information, back orders, etc. Wherever you can, automate customer communications to save valuable human resources. Save your customer service teams for complicated returns, customer satisfaction issues, and the inevitable “Karen’s” that peak season brings. Do your very best to under-promise and over-deliver.

#6 Implement and Test IT Infrastructure

Nothing is more stressful than when your entire IT infrastructure crashes, especially during the greatest profit-making season of the year. Start today by researching, selecting, and implementing new IT infrastructure. From inventory management systems to email marketing efforts, ensure all the systems are tested and implemented early. These early tests will help iron out the kinks to ensure a smooth and seamless peak season.

#7 Prepare for Returns

Returns are annoying any time of the year, but they can cripple your peak season fulfillment. Returns eat up resources like no other aspect of your e-commerce business. Most e-commerce owners would like to avoid returns altogether, and there are ways to reduce returns. However, avoiding returns 100% of the time is unrealistic. First and foremost, now is the time to prepare a procedure to manage and minimize returns. To begin with, how will a customer start the return process? Moreover, what can they expect to happen next? Undoubtedly, it should be easy, straightforward, and exchange-driven. Generally speaking, the work of processing returned products and updating inventory is often handled by your 3PL partner. In conclusion, ensure every aspect of the return process is clear to both customers and fulfillment partners that will be receiving returned products.

Returns are annoying any time of the year, but they can cripple your peak season fulfillment. Returns eat up resources like no other aspect of your e-commerce business. Most e-commerce owners would like to avoid returns altogether, and there are ways to reduce returns. However, avoiding returns 100% of the time is unrealistic. First and foremost, now is the time to prepare a procedure to manage and minimize returns. To begin with, how will a customer start the return process? Moreover, what can they expect to happen next? Undoubtedly, it should be easy, straightforward, and exchange-driven. Generally speaking, the work of processing returned products and updating inventory is often handled by your 3PL partner. In conclusion, ensure every aspect of the return process is clear to both customers and fulfillment partners that will be receiving returned products.

#8 Plan to Launch Big Sales Early

When the Pumpkin Spice Lattes start rolling out, it is an excellent time to release your biggest sales for the peak season. It may seem too early for some, but this is the best way to encourage early purchases. Launching early promotions will help spread out the crush of orders in mid-December. Retail giants like Walmart and Target extend Black Friday deals throughout November and December. If they do it, why shouldn’t you? Encourage early shopping with loyal customers by offering early sales release dates that are exclusive to them. If you want to train your consumers for next year, limit it to October only! Train your customers to purchase early. Even if they miss it this year, they will not want to miss out next year.

#9 Select a Reliable 3PL Partner

A good 3PL partner can make or break your peak season. 3PLs are fulfillment experts that help with a myriad of crucial aspects to prepare for peak season fulfillment. A 3PL like Falcon Fulfillment can help balance your inventory, leverage their multi-site distribution channels, help with return management procedures, prep goods, and staging spaces, as well as offer reliable and accurate inventory management.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, therefore understanding the roll of Third-Party Logistics is integral to keeping up. In light of this our beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

The services of a top-notch fulfillment partner don’t end there. However, don’t wait until you NEED a 3PL to begin the partnership.

Start the conversation today so that your peak season fulfillment is seamless.

Let’s Talk!

Is E-commerce Headed Toward a Recession?

Is E-commerce Headed Toward a Recession? What to Know + What to Do

Is e-commerce headed toward a recession? Is the country? Globe? All signs are pointing towards a shrinking economy. The National Bureau of Economic Research (NBER) is the official entity responsible for determining when we are in an actual recession. There are a few different definitions of what constitutes a recession. For this article, we will use the same criteria used by NBER. According to them, a recession is a significant decline in economic activity spread throughout the economy. The primary identifiers include economic productivity and employment. Is the United States and, more specifically, e-commerce headed toward a recession?

Consumer Spending

For this article, we will use statistics involving consumer spending habits (e-commerce sales and productivity) as our first criteria in determining whether we are in or headed for a recession. According to McKinsey, consumer spending is up more than 18% over projections based on pre-COVID statistics. Despite inflation rising to 8.5% in March 2022, US consumers are still shopping online at higher than expected rates. Economists attribute this to the savings stockpiled during the pandemic.

What happens once that savings buffer gets used up? No one knows, but shrinking consumer spending is expected if interest rates and inflation continue to rise. For the time being, consumers continue to purchase goods online at a higher rate than in previous years.

Unemployment

The second indicator that e-commerce could be headed for a recession is seeing an increase in unemployment. If you have visited a fast food restaurant in the last seven months, you are well aware that companies still need employees. David Wessel, head of the Hutchins Center, states that there are at least two vacancies for every person currently unemployed and looking for work. That certainly doesn’t feel like a recession.

With unemployment sitting at 3.6%, the lowest in decades, it appears that jobs are still plentiful. That being said, many financial experts, including lead economists for Bank of America, predict an increase in unemployment as inflation and interest rates rise.

Considering these two elements, we might be satisfied that e-commerce is not headed for a recession. However, due to the economy’s instability, raising concerns about inflation and long-term unemployment equal to the Great Depression, now is the time to prepare for a recession. Here are some tips to help e-commerce businesses ride out a recession.

E-commerce Recession Proofing Tactics

Back to the Basics

Finding yourself in a recession without a cash flow plan or balanced budget will make enduring the economic downturn 10x more painful. Here are some of the critical basics to help recession-proof your business.

Cash is king. This is never more true than during a recession. Take stock of your business’s cash flow and ensure you have a good handle on your monthly burn. Use your cash projections to modify and update your operating budget accordingly. Evaluate your current workforce needs and identify gaps or overages that would be the first to change if times got tough.

In addition to determining workforce needs, spend time cross-training employees. Upskill them in such a way that should you need to reduce employee overhead; you have people who can step in to keep the business running even if productivity is slower. Measure, measure, measure your marketing! Make sure your marketing efforts are working, and modify them now if they are not! Lastly, focus on what you do best. Going into recession is painful, but concentrating on your niche can set you apart. This is never more critical than when wallets and purchasing power tightens.

Manage Debt and Secure Capital Sources

Before you need the money, get the funding. The worst possible time to ask for money is when you are desperate. This is true in personal finance and business finance. Recession-proof your business by exploring capital resource options now. Get pre-approved for short-term business loans or lines of credit. Research and begin building relationships with capital investment firms that could have the ability to throw you a lifeline if a recession lasts longer than cash flow and savings can sustain.

The other financial focus should be getting out of debt. Having high debt in a recession is an albatross. Paying high debt premiums will slow down momentum and tank your business. Work on paying down debt, so you have more margin to work with during a recession.

Keep Current Customers Happy

Did you know? According to a marketing metrics study, the probability of landing a new customer is only 5%-20%, while selling to an existing one has a 60%-70% success rate. Best practices before, during, and after a recession include exclusive opportunities for loyal customers. Providing them with discounts and sneak peeks at new products. Involve your customers in your marketing efforts by interacting on social channels and offering customized deals and promotions in exchange for reviews, shares, and likes. Let your customers sell you! Invest in memorable unboxing experiences and curated add-on products. Throw in freebies, especially if you have some underperforming inventory you need to liquidate.

Double Check Inventory Management Processes

The number one reason customers leave their brand of choice is when a product is out of stock or unavailable. Now is the time to review your inventory management processes and ensure adequate inventory levels and accuracy. A trusted inventory management system will help forecast sales and minimize low stock or out-of-stock situations.

In addition, invest in flexible warehousing options when possible. Do not pay for the storage you don’t need. If you are being charged a flat rate, it is time to find a new partner.

Nurture Partner and Supplier Relationships

Relationships will make a big difference if e-commerce is headed toward a recession. Spend time and intention reaching out to critical partners, vendors, and suppliers. Offer them flexible terms if the economy declines. Focus on building stronger ties to those who will make the most significant difference to your business in a recession. Whether it is suppliers or partners, ensure they have heard from you and have an open line of communication. Recession-proofing your e-commerce can also involve leveraging relationships your partners may have access to. Start asking which key vendors to contact to ensure you are in a great position if and when a recession hits.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, therefore understanding the roll of Third-Party Logistics is integral to keeping up. In light of this our beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

Utilizing fulfillment strategies in times of economic uncertainty becomes a crucial factor for companies aiming to establish stability and drive expansion. By embracing these specialized recommendations, one can effectively address obstacles and emerge more resilient in challenging circumstances. For personalized advice on enhancing your business’s fulfillment methods, consider reaching out to the professionals at Falcon Fulfillment.

If you’re ready to start the transition or have questions, contact us to learn more about our services.

Let’s Talk!

The Metaverse and E-commerce

The Metaverse and E-commerce

The metaverse is the combination of several technological innovations that operate seamlessly together. The metaverse is built on cryptocurrency and blockchain technologies designed to facilitate digital asset transactions and activities. Unlike other platforms, the metaverse provides an identity protocol that allows users to register their aliases and manage their digital identities. The metaverse and e-commerce have always been linked, but they are becoming more integrated.

Metaverse Will Accelerate Product Discovery

Augmented reality (AR) is already a considerable component of the metaverse system. Shoppers are trying on eyewear and seeing how new furniture fits in their homes through AR. This type of shopping experience will continue to expand. Furthermore, in the metaverse, shoppers can create unique storefronts. Aligned brands will be able to target customers with similar tastes specifically. Because there are no geographic limits to who can experience the virtual store, e-commerce brands can instantly take their product to a global audience.

Immersive Digital Shopping Experiences

As mentioned, the shopping experience will become more personalized and immersive as the metaverse melds into e-commerce. We will see more VR-based shopping experiences where customers can explore products and environments from the comfort of their own homes.

Thought leaders in the e-commerce space have already begun building branded virtual worlds. Shoppers will soon be able to pick up products, inspect them, and determine whether or not they will purchase, just like in a brick-and-mortar shop. Shopping in the metaverse might be more fun than we ever imagined. Just think you could visit Nike town and chat with your favorite sponsored athletes!

Social Proof and Social Experiences

A new term, “social proof,” is popping up as an e-commerce buzzword. Simply put, it is the growing effect of how our online social communities influence our purchases. The metaverse and e-commerce will continue to see a rise in product reviews, social media integrations, and even social shopping experiences.

Friends will be able to shop in virtual stores together. They will be able to try on clothes, talk, and even buy each other gifts…together. Furthermore, influencers and celebrities can host social shopping events, promotions, and parties and reach a much larger audience than is possible with a physical event.

Personalization Done at Scale

Consumers will have the ability to create unique identities in the metaverse. These profiles will inform e-commerce brands of crucial facets of their shopper and allow them to personalize suggested items, colors, tastes, and preferences. The more a consumer purchases, the more personalized their experience will become. The metaverse will not be where you have to wade aimlessly through piles of products to find the one you were looking for. The metaverse will allow e-commerce brands to find and assist their core clients easier than ever.

Blockchain Technology & Cryptocurrency

With the advent of blockchain technology, a new batch of e-commerce players are emerging. This technology allows for a more secure, fast, and transparent buying and selling experience. The metaverse uses a form of cryptocurrency called (EFTs) that has allowed purchases to be processed quickly, securely, and transparently from around the world. The technology and platform are opening up the online shopping experience to anyone.

The metaverse will revolutionize e-commerce. From expanding brand awareness to immersive shopping experiences, our online purchases will be very different in the near future. E-commerce brands poised to do well are willing to create a dynamic virtual store, are ready to fulfill orders quickly, and have partners to help them scale quickly.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, therefore understanding the roll of Third-Party Logistics is integral to keeping up. In light of this our beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

E-commerce brands entering the metaverse won’t need substantial physical retail stores, but they will need flexible warehousing spaces. They will need a team of fulfillment experts ready to receive, package, and ship out the ultra-personalized packages found only in the metaverse. Falcon Fulfillment are memorable unboxing experience experts. What better way to differentiate your e-commerce in the metaverse than pairing immersive, personalized shopping with a unique, branded, unboxing experience?

Let Falcon Fulfillment usher you into the next generation of e-commerce shopping.

Let’s Talk!

Q2 E-commerce Trends of 2022

How are E-commerce Trends Changing

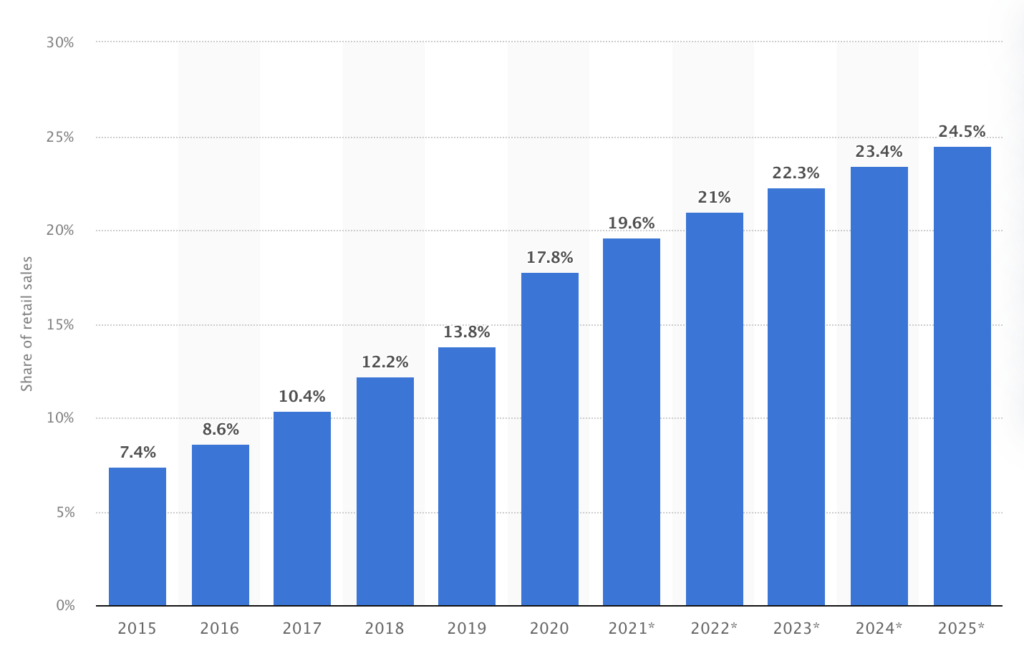

The pandemic of 2020 pushed the world into faster technological advancement. Typical growth rates of 13-15%, shot up to 31% growth in 2020. Now, three years later, we can expect faster advancements, delivery, and speedy checkouts. Each quarter we see a new wave of e-commerce trends that will affect the bottom line of businesses around the world. Let’s review the e-commerce trends of Q2.

E-commerce Trends of Q2

The E-commerce Landscape is Becoming More Competitive

By the end of 2022, e-commerce accounted for 20.4% of worldwide retail sales, up 10% from five years previously. This fast expansion of e-commerce is linked to a variety of factors, however, Covid-19 is the most prominent.

When stay-at-home orders began in early 2020, businesses made a swift transition into the online world. This technological jump pushed companies and consumers alike into a buying journey they had never experienced, which ultimately ignited the ever-burning flame of digital shopping that we continue to see today.

Three years later, and despite brick-and-mortar retailers are making a comeback, e-commerce remains supreme. Because of the rise in online shopping, thousands of e-commerce retailers sprung up almost immediately after the pandemic began. This trend shows no signs of slowing and with each passing year, the e-commerce sector becomes more crowded and more competitive than ever. Successful startups are becoming more difficult to manage, and established e-commerce are encountering more frequent and aggressive competition. As newcomers drive pricing down to attract buyers, established retailers struggle to maintain market share and jobs.

Increasing Advertising Costs and Reduced Campaign Effectiveness

As new e-commerce businesses flood the market, all are vying to find and attract the attention of customers. This raises the overall cost of advertising and lowers the total return on ad investments. For example, Facebook advertising costs 47% more than it did the previous year, and this trend is only anticipated to continue. Furthermore, as a result of Apple’s new privacy update in iOS 14.5, cross-app data sharing is now restricted unless users voluntarily opt in. Because the vast majority of customers want to protect their privacy, data sharing is often denied. This raises the cost and lowers the effectiveness of Facebook and Instagram advertising.

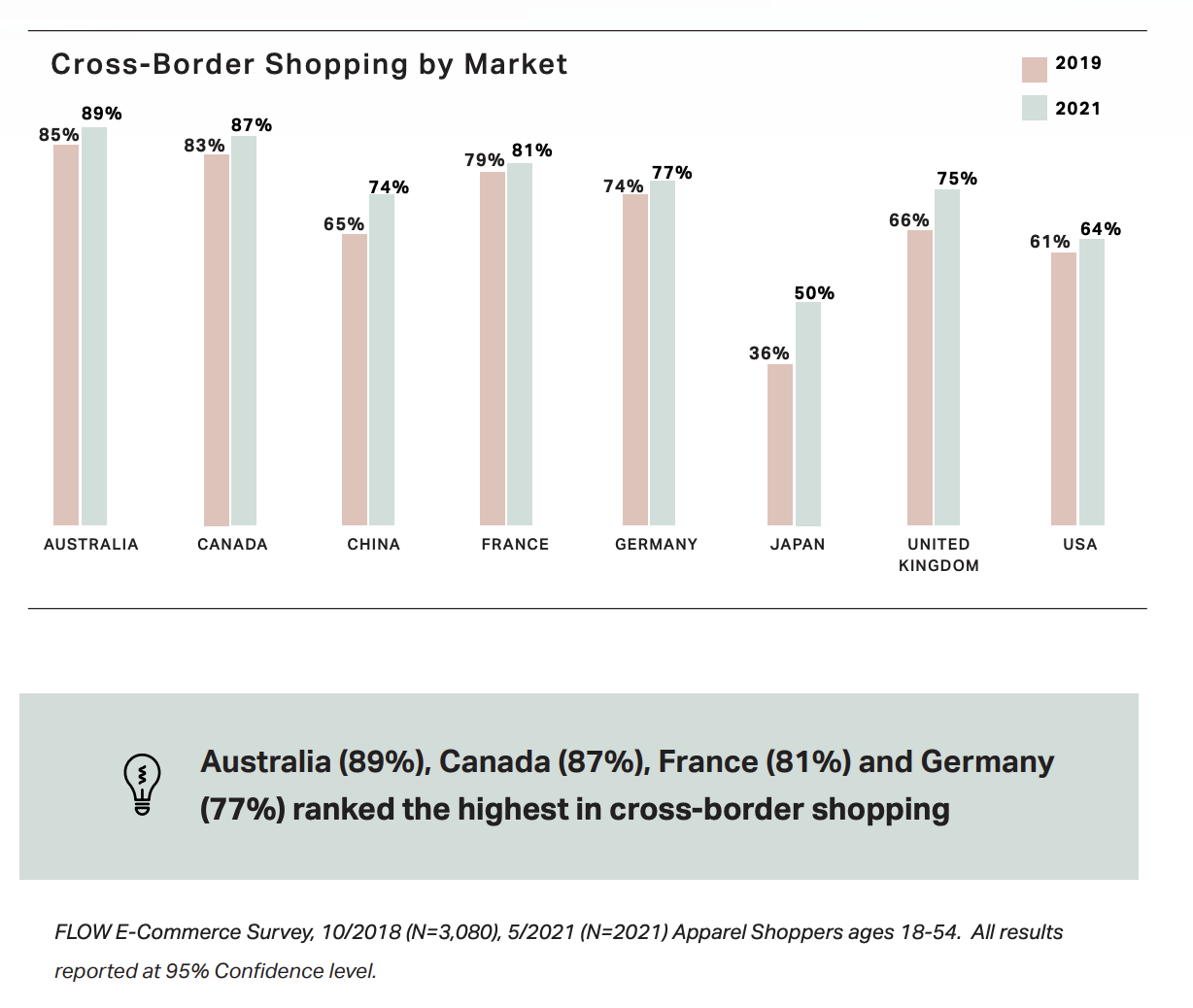

E-commerce Globalization to Avoid Growth Bottlenecks

The total addressable market (TAM) is a common constraint for e-commerce growth and expansion. As companies hit their local and domestic consumer limitations, e-commerce brands will soon venture into the global arena to expand their reach. Not only will this help e-commerce reach more consumers, but it will assist shoppers in finding new and foreign brands. According to a recent poll, 76% of online shoppers have made purchases from an e-commerce site outside their own country, solidifying the future global expansion of e-commerce.

Localizing Supply Chain to Reduce Manufacturing Costs

e-commerce is seeking more cost-effective solutions as supply chain delays and interruptions persist far beyond 2020. With raw material shortages and rising air and sea freight costs, business owners are moving to a more localized supply chain. Companies are shifting from low-cost production in China and toward higher-priced manufacturing and distribution in the United States. Businesses are choosing a local distribution facility to avoid record-high freight costs, delayed inventory, and delayed shipments. Although localizing your production may cost more upfront, your customers will receive orders faster, inventory will remain stocked, and transportation and distribution expenses will be reduced, possibly saving you hundreds in the long run.

Get Monthly Updates on Supply Chain News

Partnering with a 3PL

Prior to 2020, 3PLs were leveraged by most fortune 500 companies around the world. Now, post-pandemic, not only do 90% of fortune 500 still works with 3PL partners, but small to mid-size e-commerce businesses are making the switch as well. This is due to increased awareness of the enhanced efficiency and reduced fulfillment costs that 3PLs can provide. Working with a 3PL allows e-commerce businesses to better optimize fulfillment, scale flexibly, minimize inventory shortages or delays, adopt the best shipping rates, and even provide sustainable solutions and alternatives to reduce a company’s carbon footprint.

Learn more about partnering with a 3PL

Renewed Focus on E-commerce Sustainability

Consumers and businesses alike are becoming more environmentally conscientious. This has ushered in new trends of sustainability, ethically sourced products, and morally sound business models. Shoppers are are choosing more sustainable options over cheaper or faster alternatives. Because of this, e-commerce are quickly making the switch toward sustainable packaging, waste minimization, renewable energy, and a more people-focused business strategy.

Learn more about E-commerce sustainability

Alternative Payment Options

In the wake of high inflation, consumers are adjusting spending habits and shifting towards more frugal budgets. They are sacrificing non-essential items and services, leaving some e-commerce wondering what to do. Thankfully, the buy-now-pay-later (BNPL) options that appeared in 2020, are quickly growing in popularity. Afterpay, Sezzle, and Affirm are examples of popular BNPL options that are slowly taking preference for many shoppers. Whether BNPL options are used to work with inflation, offer financial flexibility, or something else entirely – any e-commerce will benefit from introducing BNPL options at checkout.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, therefore understanding the roll of Third-Party Logistics is integral to keeping up. In light of this our beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

At the end of each quarter, there are bound to be new trends for your e-commerce to capitalize on. From e-commerce globalization and localized manufacturing to 3PL partners and higher competition, it’s tough out there.

Make sure to follow along with Falcon to get up to speed on the latest consumer and e-commerce trends.

Let’s Talk!

1PL, 2PL, 3PL, 4PL, 5PL: Logistics Providers Explained

Logistics Providers Explained

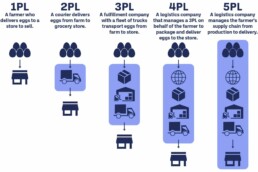

The majority of business owners have heard the phrase “3PL” or other “PL” terminology. What most people don’t realize is that there are many tiers of logistics providers, and their services vary based on the needs of your company.

In this article, you will learn the distinctions between logistics providers to help you determine which type is best for your company.

1PL – First-Party Logistics

A First-Party Logistic Provider is made up of two parties, the supplier and the retailer/customer. A 1PL logistics provider transports items from stock to shelves. In this type of relationship, the supplier manages their own inventory, storage, and delivery.

2PL – Second-Party Logistics

Second-Party Logistics Providers focus solely on the transportation sector of business. Examples of 2PLs include airlines, shipping lines, and hauling companies that operate the vehicles. 2PLs transport inventory between one or more legs of the fulfillment journey.

3PL – Third-Party Logistics

Third-Party Logistics is an industry term most are familiar with. For companies looking to outsource their entire logistics process, 3PLs are the answer. They are able to handle the management of receiving, inventory warehousing, packaging, and shipping services, letting e-commerce businesses focus on other important areas of their company. Some 3PL businesses offer additional logistics services known as value-added services. These include inventory management, kitting and assembly, and more.

According to Armstrong and Associates, 90% of Fortune 500 companies use a 3PL.

4PL – Fourth-Party Logistics

Fourth-Party Logistic Providers act as consultants. While their services are similar to a 3PL, they lack the physical means to move inventory through the supply chain themselves. Instead, a 4PL will contact and negotiate services between the necessary companies on your behalf.

5PL – Fifth-Party Logistics

A Fifth-Party Logistics Provider, or 5PL, is a consultant that operates at a level above a 4PL. Essentially, 5PLs serve as aggregators for 3PLs by bundling the needs of multiple 3PL businesses to secure better rates on services. When working with a 5PL, you can expect a fully integrated logistics solution that encompasses the entire supply chain from beginning to end. This is achieved through the coordination of multiple outsourced logistics providers, ensuring a seamless and efficient process.

The Sweet Spot

Similar to the story of Goldilocks and the Three Bears, supply chain providers are their own metaphorical bowls of porridge. Some are too cold, simple, and bland. Others are too hot, complex, and hard to understand. However, there is one porridge that comes at just the right temperature, provides just the right amount of support, and allows your e-commerce to successfully grow and scale. 3PLs are the sweet spot of supply chain service providers. With full control mixed with the support you need from fulfillment experts, you’re free to focus on more important aspects of your business while your fulfillment seemingly manages itself.

The Bottom Line

A 1PL partner is the simplest system and doesn’t require excessive integration or networking. Your business has full control over the supply chain process, however, your ability to scale will be limited and the risk of supply chain obstacles will increase.

A 2PL also uses a simpler system, but it does not offer as many logistics solutions as other supply chain providers.

Once your company is in a position to consider 3PL services, it’s time to transfer some aspects of your business over to the experts. These aspects are various parts of the fulfillment process that take the most time and precision, including but not limited to warehouse storage, inventory management, order processing, and order assembly. While these aspects are outsourced, your business still retains control and final say.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, therefore understanding the roll of Third-Party Logistics is integral to keeping up. In light of this our beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

If you’re interested in outsourcing your entire supply chain process, a 4PL or 5PL are great options depending on the needs of your company. However, businesses that outsource with a 4PL or 5PL tend to have less control over their supply chain and final-say decisions. If you’re searching for a reliable 3PL partner, look no further. At our company, we own and operate dual warehousing facilities strategically located nationwide. Our multisite infrastructure enables us to efficiently distribute inventory nationwide while simultaneously reducing transit times and shipping costs.

If you’re interested in streamlining your logistics operations, don’t hesitate to reach out. Talk to one of our knowledgeable agents today to learn more about how we can help your business thrive!

Let’s Talk!

Utah Fulfillment Services

Utah Fulfillment Services with Falcon Fulfillment

If you’re interested in expanding your e-commerce from shore to shore, a 3PL partner is the best way to go. With Falcon’s strategically placed warehouses, utilizing reputable and streamlined fulfillment services to reach east and west-coast customers is more than possible – it’s easy … and it saves you time and money! Let’s take a look at why Falcon Fulfillment is an excellent choice when choosing a fulfillment partner.

Why Fulfill with Falcon?

Fast, Full-Service Onboarding

When working with other fulfillment centers, onboarding new clients can take weeks or even months. With Falcon, we get new partners completely onboarding in a matter of a few short days or weeks – but never months. (Our quickest onboarding record is 4 days … Just saying.) We make it happen by handling the hard work when connecting your supply chain to our warehouses and integrating your software with ours, all with a fulfillment expert for every step of the way.

Pick it, Pack it, 2-day Ship it

Never miss out on 2-day shipping. In our fulfillment services we pick, pack, and ship orders the same day they’re placed with a 99.996% accuracy. Additionally, we synchronize all shipments with carrier pick-up times to ensure orders reach customers as quickly as possible.

Personalized Service that Scales with You

Falcon can scale with you in a variety of ways while still providing hassle-free options to personalize the customer experience and customize order fulfillment. From warehouse flexibility and on-demand fluctuations to custom packaging and kitting services, Falcon is here to benefit your business. In every way that makes it unique.

Dedicated Account Managers

With Falcon Fulfillment, you get a dedicated account manager that’s there for you every step of the way. No more calling in and waiting on hold to reach a 3PL representative. Enjoy direct and transparent communication with professional support appointed specifically to you and your e-commerce fulfillment services needs.

Custom Packaging and Kitting Services

Our kitting services include adding labels or tags, assembling products into a kit with a new SKU, adding custom printing or numbers, and assembling components before shipping. Un-kitted products may also be returned to their original SKUs. As a result, you can keep your inventory flexible to meet fluctuating demands.

Transparent Cloud-Based Inventory Reporting

With Falcon Fulfillment, you unlock the Falcon Portal. Onboarded clients use our Falcon Portal to access transparent inventory and fulfillment details, stock movement updates, and even access a real-time inventory snapshot every day at midnight to make sure you’re always on the same page as your fulfillment partner.

24/7 Alarm and Video Surveillance Security

Our warehouse undergoes 24/7 video surveillance and is programmed to alert emergency services as needed. These security measures establish our warehouse as a safe, reliable, and secured location for receiving, storing, and delivering your inventory.

Extreme Temperature Controls

Don’t worry about hot or freezing inventory. Our warehouse ventilates and insulates appropriately to maintain merchandise coolness and dryness. Throughout the year, we maintain the ideal temperature of 50-70 degrees in our warehouse to ensure high inventory quality.

In-House Fulfillment Services Tech Team

Our in-house IT department sets Falcon Fulfillment apart from other fulfillment centers that often outsource their developers. With an in-house tech team, we have the ability to quickly solve technical issues, create custom API’s, and utilize a proprietary WMS that offers an easy-to-use portal for customers to view stats and other relevant inventory information in real-time.

Total Billing Transparency

There is no other fulfillment facility that provides complete billing transparency! We offer itemized invoices for each and every order so you know precisely where your money is going when you use our fulfillment services.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, therefore understanding the roll of Third-Party Logistics is integral to keeping up. In light of this our beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

With our streamlined logistics services, coupled with access to our Falcon portal and the support of dedicated account managers, partnering with us offers a unique advantage for your e-commerce operations. Furthermore, we alleviate the burden of order fulfillment by entrusting it to our in-house experts, who excel in the art of seamless delivery.

We’ll handle all your fulfillment services so you can focus on building your business.

Let’s Talk!