Choosing a 3PL Partner for E-commerce Order Fulfillment

Guide to Choosing a 3PL Partner for E-commerce Order Fulfillment

Choosing the right 3PL partner for e-commerce can make the difference between a highly profitable and highly frustrating relationship. It can feel overwhelming when starting to look for a new fulfillment partner. You must be patient, clearly understand what you want, and know the industry standards. There are some key criteria to consider to find the right fit for your e-commerce needs. This guide will share the steps and aspects of choosing a 3PL partner for your unique e-commerce business.

Indications it is time to switch 3PL providers.

When it comes to knowing when it’s time to switch 3PL providers, there are several signs to examine. The first is a decline in customer service. This can come in the form of bad reviews, delayed shipping, order and inventory errors, or delays. If you find that your provider can no longer meet your customer service needs, or if you’re not getting a timely response when you have an issue, then it’s likely time to move on. Another sign is if you’re consistently running into problems with the process: delayed shipping, receiving, slowing order cycle times, or incorrect orders being sent out. Lastly, if your 3PL provider can no longer accommodate your company’s growth or changes, it’s time to look for a provider that can.

Qualifications to look for when choosing a 3PL partner.

Streamlined Shipping Operations

It should come as no surprise that topping our list is streamlined shipping operations. After all, this is the quintessential service offering of a 3PL fulfillment partner. Ensuring customers receive what they order promptly is a fundamental requirement of any e-commerce order fulfillment partner. However, not all 3PL companies are created equal when it comes to their shipping operations. When choosing a 3PL partner, ensure they leverage automation in their shipper operations, including shipping labels, multiple carrier relationships, multi-site distribution centers, and real-time inventory tracking. These additional features improve shipping times and accuracy.

7 Day Operations

3PL providers that offer continuous operations can provide you and your customers with a higher level of service. 3PLs with 24//7 service process orders more quickly, decreasing shipping windows and allowing for 1-2 day delivery for most orders in the US.

Multi-site Distribution

How close is the warehouse to your manufacturer and your customers? Selecting a fulfillment provider with multi-site distribution lets your business offer faster deliveries. Choose a provider that is easily accessible to you so you can tour a property near you. This not only gives you peace of mind but also affords you the ability to direct aspects of the fulfillment process when needed. This is especially true of brands with custom or personalized packaging requiring special handling.

Communication

Most relationships that end poorly have done so because of a lack of clear communication. It is impossible to solve problems without an open line of communication. It is vital to choose a 3PL partner that provides you with assurances about how communications occur. Solid e-commerce fulfillment partners will offer 24/7 real-time data for orders, inventory levels, etc. Some providers even have a dedicated account manager to troubleshoot specific issues. Determine the appropriate communication level and make certain the channels, people, and processes are clear before you engage with a new partner.

Scalability

Many e-commerce brands switch providers because they can no longer service the number of orders or are limited by the regions where shipping is available. Regardless of the reasons, this restricts growth. As you interview new 3PL partners, it is crucial to evaluate their capacity limits. Look at current limitations as well as projected limits. You don’t want your provider to run out of warehouse space or be unable to accommodate an influx of new customers. Your company should share existing order volumes and where you hope to be in the next few years.

Experience and Expertise

When choosing a 3PL partner for your e-commerce fulfillment needs, ensure they have a long and consistent history as a service provider. This will help confirm they have adequate experience and expertise in order fulfillment. Unfortunately, as e-commerce boomed, so did sub-par 3PL providers. It is important to do your research to find the right match. A solid partner will have years of experience, expertise in your industry, and a verifiable track record. Ask to speak directly with the staff you will be working with; this will give you a good indication if your 3PL employs and trains knowledgeable staff.

Expansive Carrier Network

Most 3PL partners have relationships with numerous carriers, but it is essential to understand if those relationships are in networks where you most often deliver. For example, if DHL is the primary carrier in a specific sales region, you must ensure your partner has a relationship with them. Furthermore, many 3PLs benefit from carrier parcel discounts because of their volume of orders. Discuss what discounts might be afforded your e-commerce due to the partnership.

Review Value-Added Services

Each 3PL partner will offer a different variety of value-added services. From kitting and assembly to reverse logistics, determine which additional services are necessary or desired for your e-commerce business. Here are a few standard value-added services to consider when choosing a 3PL partner.

- Kitting and Assembly – Kitting and assembly services include Adding labels or tags, assembling items into a kit with a new SKU, adding custom printing or numbers, and assembling components before shipment. Kitting and assembly services are commonly used when creating product bundles, promotional sales packages, and subscription boxes.

- Custom or Branded Packaging – Many 3PLs like Falcon Fulfillment enable you to completely customize your packaging. They help you personalize every part of your package, including the material, size, style, insert, packing tape, etc. In addition to personalization, an ideal partner will help ensure the right size and eco-friendly packaging.

- Returns Management – Reverse logistics and returns management is a time-saving value-added service provided by great 3PL partners. This eliminates the need for a separate location to execute refunds and exchanges and add inventory back to the warehouse when possible. Returns occur in approximately 20-40% of online purchases, so it is vital to have a streamlined system to process them quickly.

Sustainability

Sustainability has been a growing e-commerce trend for several years now. Consumers are looking to support companies committed to building a sustainable future. The transportation and fulfillment industry has not always been environmentally aware. However, the customers have spoken through their wallets that ensuring eco-friendly practices are a priority. When choosing a 3PL partner for your e-commerce order fulfillment, ask how they work toward a sustainable future. Here are a few ways a 3PL partner can help create a sustainable business:

- Reduce transportation emissions

- Sustainable packaging options

- Optimized energy usage (in warehousing and with vehicle fuel sources)

- Streamline reverse logistics

Transparency

Being left in the dark about inventory, stock levels, or delivery statuses is poor service and bad for your business. Determine what information your potential 3PL partner shares, when that data is regularly shared, and what the processes are if there are issues. A solid 3PL partner should behave like a teammate. They don’t try to hide aspects of business operations vital to success. Ensure the necessary information and communication are discussed before engaging with a new 3PL.

Culture Matching

While this might seem like a low priority, matching company culture can mean the difference between a thriving and symbiotic partnership and a parasitic one. When you match culture, you ensure that the principles you share are carried out to their full potential. Questions to consider are:

- What values do they appear to uphold?

- Do they have a mission statement? Does it match or complement your own?

- Do you have similar priorities?

There are many things to consider when choosing a 3PL partner for your e-commerce order fulfillment. The process can initially feel overwhelming, but the key is to fully evaluate the new relationship. A solid 3PL partner can improve your business outcomes and profitability and even open new doors of opportunity, so the choice should not be rushed. Take your time and ensure your new 3PL will provide the necessary services and align with similar values and culture to help your e-commerce succeed. Are you considering a switch? Let Falcon Fulfillment help your e-commerce business thrive.

Get in touch today to learn more about us!

Let’s Talk!

E-commerce Order Fulfillment 101 - What you need to know

E-commerce Order Fulfillment 101 – What you need to know

A solid e-commerce order fulfillment strategy is the center of your business success. After all, getting orders into the hands of consumers quickly, effectively, and with a high customer satisfaction rate is fuel for growth. A company that doesn’t fulfill orders well will fail fast. It is essential to understand what fulfillment is, the elements involved in the process, and what types of fulfillment offer the best benefits for my company. This article will outline what e-commerce order fulfillment involves, the different kinds of fulfillment, and the key indicators it is time to outsource fulfillment.

What is e-commerce order fulfillment?

Fulfillment is the process of getting a product delivered once an order is placed. It involves receiving, inventory storage, order processing, picking, packaging, shipping, and returns management. Order fulfillment consists of every aspect of the product journey, from receiving to final-mile delivery.

Basic Steps of E-commerce Order Fulfillment

Inventory Receiving

Products are received, counted, and checked for quality when they arrive from the vendor or manufacturer. This can occur at any location but typically happens at a warehouse, distribution center, or fulfillment center. Some small e-commerce businesses manage this aspect of fulfillment out of their own homes. However, once orders hit a threshold that overwhelms your living room, basement, and garage, it is probably time to outsource fulfillment. Regardless of the location of receiving, it is crucial to verify the accurate quantities, quality, and type of products before incorporating them into the inventory management system.

Inventory Storage

After receiving and inputting products into the inventory management system, the next step is to prepare them for storage. Stock and shelve items strategically to minimize the time required for order fulfillment. The key is having a well-organized warehouse. Optimize your fulfillment process by implementing inventory management best practices.

Order Processing

Order processing begins when a customer places an order. The order details are sent to the inventory management system that triggers product selection from the warehouse or storage area. Once the product(s) are selected they are then packaged for shipment.

Shipping

The package is loaded onto a shipping carrier transport and begins the journey to the customer’s address. This part of the journey can involve multiple types of transportation and carriers depending on the size, shape, and requirements of the final-mile delivery.

Returns Processing

Order fulfillment extends beyond the customer receiving their package; it concludes when the customer expresses satisfaction with their purchase. This is why returns are the final aspect of e-commerce order fulfillment. When your business grows to a size where returns become a time-soak, it is probably time to outsource fulfillment and returns management to a larger expert team.

What are the different types of e-commerce order fulfillment?

There are generally three main types of order fulfillment. They include; in-house, dropshipping, and 3PL fulfillment. A fourth type, a hybrid, can involve a cross-section of all three types depending on volume and product types.

In-house fulfillment

In-house or in-store fulfillment is when a company fulfills its orders from its facilities, labor, and resources without the assistance of a third-party provider. Most companies begin by fulfilling orders in-house because it is the most cost-effective fulfillment option that allows for the highest level of control.

Dropshipping

Another popular fulfillment option involves fulfilling orders directly from the manufacturer or vendor without going through the typical fulfillment channels, known as dropshipping. Dropshipping is convenient and affordable but offers limited control over the quality and quantity of inventory. Understanding the pros and cons of dropshipping can help you decide if this is the right fit for your e-commerce brand.

3PL Fulfillment

Third Party Fulfillment (3PL) is where the entire order fulfillment process is outsourced to a third party. These teams specialize in every aspect of e-commerce order fulfillment. They have flexible warehousing, labor, and resources to ensure your business can scale quickly. If you want to maintain tight control of every aspect of order fulfillment, a 3PL may not be suitable for you. However, if you have outgrown your warehouse space or your team is overwhelmed with demand, it might be time to outsource fulfillment.

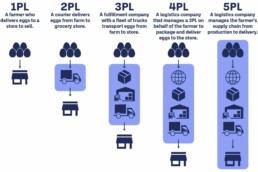

What is the difference between 1PL, 2PL, 3PL, 4PL, and 5PL Fulfillment?

There are slight differences between the different “PL” providers. 1PL fulfillment involves a supplier fulfilling their orders directly, whereas a 2PL consists of a transportation partner like FedEx, UPS, or USPS. A 3PL is a more extensive operation that alleviates more of the order fulfillment journey. 4PL and 5PL companies take on a more significant role as order fulfillment concierges. The following image illustrates the difference between the different logistics providers.

When should you partner with an e-commerce order fulfillment service provider?

- You no longer have the time to focus on your core competencies

- You have outgrown your warehouse space

- Your team is overwhelmed by the demand

- Order errors and returns are increasing

- You know you are paying too much for shipping

- You want to expand into a new market or location (International)

This post about e-commerce order fulfillment is just the tip of the iceberg. There is a whole industry that handles the logistics surrounding order fulfillment. When you first launch an e-commerce business, it can be daunting to know how to get your orders to your customers quickly and effectively. Keeping your customers in mind is the most important aspect of building your business. If satisfying your customer is your top priority, it will guide every decision, including what is the best fulfillment option.

Discover how Falcon Fulfillment can ease the challenge of timely order delivery. Contact one of our knowledgeable agents today to learn more.

Let’s Talk!

Health, Wellness, and Beauty Fulfillment

Health, Wellness, and Beauty Fulfillment

The health and beauty industry has seen a massive surge in demand over the past few years. People are investing in their health and beauty needs more than ever before. According to a report by CommonThread, the beauty and personal care market will reach a whopping $784 billion in sales by 2027. With this increased demand comes the challenge of fulfilling orders quickly and efficiently. Health, wellness, and beauty fulfillment have unique challenges that other verticals do not. The receiving, storing, packing, and shipping of beauty products require additional care and supervision. This article will discuss the challenges of health, wellness, and beauty fulfillment and the solutions to overcome them.

Challenges in fulfillment of health, wellness, and beauty-related products

Expiration Dates

Managing the expiration dates of health and beauty products can be a challenge for retailers. Products such as makeup, skincare, haircare, and other beauty products have expiration dates that are often hard to keep track of. Many products have a short shelf life and must be rotated regularly to ensure customers get the freshest products. Additionally, retailers must be mindful of the differences in expiration dates of different beauty products, as some products may expire sooner than others. Retailers must also keep a close eye on the expiration dates of returned products to ensure that customers are not purchasing expired products.

Regulating Temperatures

The challenge of regulating the temperatures of health, wellness and beauty products during fulfillment is a significant concern for many businesses. These products are sensitive to extreme temperatures and humidity changes and must be stored and shipped carefully to ensure their quality and efficacy. Temperature-controlled environments must be established, monitored, and maintained during storage and shipping to ensure that the products are not exposed to temperatures outside their acceptable ranges. It is also essential to have procedures in place to track and monitor the temperature of the products throughout the entire process, from warehouse to customer, to ensure that the products remain within their acceptable temperature range. OSHA recommends that warehouses maintain all internal companies at a range of 68-78 degrees Fahrenheit, with humidity in the approximate range of 20 to 60 percent. These standards can dramatically fluctuate based on the location of the warehouse.

Custom Packaging

Custom packaging for health and beauty products poses a unique challenge during fulfillment. These products often need to be packaged in specialized materials to ensure their safety and integrity, such as airtight containers or leakproof bags. Additionally, products may require additional protection to ensure they arrive undamaged, such as cushioning or extra layers of cardboard. This can add extra costs and time to the fulfillment process. Many of the products offered in the health, wellness, and beauty industry are expensive and vary widely in the materials used and the shape of the containers. Also, beauty brands boost their average order value (AOV) by offering multi-buy sales, buy-one-get-one, and customer bundles. This adds to the complexity of packaging multiple products within one shipment. Furthermore, ensuring the packaging complies with relevant regulations can add further difficulty. These factors make packaging for health and beauty products a challenge during fulfillment.

Expedited Shipping

Expedited shipping is essential for health and beauty products as it ensures that customers receive items quickly and safely. With the growth of online shopping, customers increasingly rely on the speed and reliability of expedited shipping to receive the beauty and health products they need. Expedited shipping is particularly critical for products that need to be stored in a cool, dry place or require refrigeration. These items can quickly become damaged if not shipped promptly. Additionally, many customers wait until they run low on a product and rely on expedited shipping to save the day. Businesses can ensure customer satisfaction and loyalty by offering the fastest available shipping.

Solutions for successful health, wellness, and beauty fulfillment/span>

FIFO method for inventory (first in, first out)

The FIFO method (First In, First Out) is a great way to maintain the quality of health and beauty products. It ensures that the oldest products are used first, thus protecting the integrity of the product. This method can be used in many ways, from stocking shelves to fulfilling orders. Retailers can use the FIFO method to ensure that their customers receive the freshest products possible. Additionally, this method helps to reduce waste by helping to prevent expired products from being sold. For retailers, using FIFO helps maintain customer satisfaction and loyalty, as customers will always receive the best products. This method requires a highly organized inventory management system and rigorous return management protocols, but it is highly effective.

Automated Inventory Management

Automated inventory management is essential to efficient health and beauty product fulfillment. This technology allows retailers and distributors to track product availability, accurately forecast demand, reduce out-of-stock, and maintain accurate inventory counts. Automated inventory management systems provide real-time updates on inventory levels and can be used to alert staff when stock is low, or replenishment is needed. Ensuring the use of a high-tech inventory system also helps manage expiration dates, boost order accuracy, and manage multi-SKU product lines. Automated inventory management improves the visibility of the entire fulfillment process, from ordering to delivery. With automated inventory management, health and beauty product fulfillment can be more efficient and reliable, ensuring that customers receive their products quickly and accurately.

Strategic Fulfillment Center Locations

Because health, wellness, and beauty brands rely on delivery speed and accuracy, it is essential to procure fulfillment centers in strategic locations. This helps with delivery speed as well as return efficiency. Beauty brands that partner with a quality 3PL with multi-site distribution have a leg up on competitors simply due to their ability to distribute products quickly.

Memorable Unboxing Experience

Unboxing experiences can be a great way to boost customer satisfaction when fulfilling health and beauty products. Customers feel special and valued when they receive a custom-branded package that is memorable and personalized. This increases brand loyalty and customer satisfaction. Big beauty brands understand that this experience can be a shareable social event. Finally, memorable unboxing experiences can help to build a brand identity, allowing customers to associate the company with a particular style and quality. When a company invests in developing custom packaging and creating an experience, it helps to drive more sales in the future.

Value-added Solutions with a 3PL Partner

As businesses fulfill health, wellness, and beauty products, it can feel overwhelming to keep track of lot numbers, expiration dates, compliance requirements, and specialized labeling for specific products. Partnering with a 3PL can help manage many of the challenges in fulfilling beauty products.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, understanding the roll of Third-Party Logistics is integral to keeping up. This beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

Here are Falcon Fulfillment, we understand the nuances of B2B and B2C fulfillment for the health, wellness, and beauty industries. We recognize certain products require special care and handling. Furthermore, our teams have worked side-by-side with brands to create custom packaging that protects the product and is sustainable.

If you want to learn more about how your beauty brand can benefit from a partnership with Falcon, get in touch with one of our amazing agents today.

Let’s Talk!

5 Indicators It's Time to Change Fulfillment Providers

Indicators it’s time to change fulfillment providers

If you are running a successful e-commerce, you have spent countless hours perfecting your product, brand, and user experience from purchase to return. In addition, you likely partnered with a fulfillment company to help deliver and grow your business. You may have started to feel dissatisfied with how things are going. Here are five crucial indicators that signal it’s time to change fulfillment providers.

Limits on where orders can be shipped

Your fulfillment partner must be able to fulfill orders wherever your customers are! Ideally, your fulfillment warehouse is near your customers. This becomes difficult as e-commerce brands grow and reach a wider audience. Scaling your business with a 3PL might be a good idea. A change in fulfillment providers can help leverage a more comprehensive distribution network and ensure deliveries can be processed quickly.

Long order processing and shipping times

Customers are more demanding than ever when it comes to shipping times. The “Amazon Prime-Effect” has solidified the idea that any product ordered from anywhere shouldn’t take more than two days to process and never more than five to arrive. If your orders take more than three days to process and ship, it could indicate it is time to change fulfillment providers. Most 3PL partners that can genuinely help your company scale will be able to process and ship an order anywhere in the continently US within 2-days. Your business could suffer if your service provider cannot consistently meet this timeline.

Inventory is taking days or weeks to be stocked and added

Accurate inventory data is crucial to a successful e-commerce. Having inventory readily available within 24-36 hours is game-changing. Nothing frustrates an e-commerce business more than knowing a large product shipment has arrived at the warehouse but sits on a pallet waiting for stocking and addition to the inventory management system. This typically indicates a lack of staff or organization. The longer this process takes, the more sales potential you lose. If it takes more than a few days to get your inventory added, it might be time to change fulfillment providers.

Confusing invoicing or billing

Managing the financial reporting of a successful e-commerce is problematic on a good day and mind-numbing on a bad day. Top-rated 3PL providers offer complete itemized billing transparency. Having a financial report that details every charge with open-honest billing can help highlight advantages and opportunities for process change. When your fulfillment partner cannot give a detailed and accurate invoice about where their charges stem from, it is time to move on. The decisions you make are only as good as the data on which they are made.

Negative customer reviews regarding shipping

Negative customer reviews are an obvious indicator it is time to change fulfillment partners, because only one bad review can drive away up to 22% of potential customers. If you have noticed more than one poor review related to shipping or final delivery, your company cannot afford to ignore it.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, therefore understanding the roll of Third-Party Logistics is integral to keeping up. In light of this our beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

Seeing that it might be time to change fulfillment providers can be daunting. The process involves confusion, overwhelm, and a lot of resources. However, at Falcon Fulfillment, we pride ourselves on onboarding new clients in days or weeks, not months. We offer a dedicated account manager throughout the onboarding process and beyond. Our team will do the heavy lifting so you can focus on growing your business. When our customers changed their fulfillment partner, we delivered!

Want to learn how working with Falcon can help your e-commerce business scale? Get in touch with one of our agents today.

Let’s Talk!

3 Advantages of a 3PL that Improve Your Bottom Line

3 Advantages of a 3PL that Improve Your Bottom Line

When running a business, one of the most important factors to consider is your bottom line. To keep your business running smoothly and profitably, it is essential to keep costs to a minimum. One way to do this is by leveraging the advantages of a third-party logistics provider (3PL). A 3PL is a company that provides a variety of services to help businesses manage their warehousing, transportation, and other supply chain needs. These services can help companies to save money, improve efficiency, and reduce the amount of time and effort required to manage the shipping and logistics process. Using a 3PL has many advantages that can help businesses cut costs and improve their bottom line.

Experience and Insight

Supply chain logistics can be complex and confusing. 3PLs typically have more resources and experience than individual business owners regarding the fulfillment industry. With the knowledge and expertise, 3PL teams can help reduce storage, transportation, and overhead costs. Additionally, they can help improve efficiency by streamlining processes and consolidating shipments. 3PLs are always informed and up-to-date on laws, regulations, taxes, customs information, and other factors that can be a nuisance to shippers. Where a business owner might go through multiple seasons of trial and error to achieve the same seamless results, a 3PL will highlight inefficiencies and offer solutions faster.

Lower Costs

A solid 3PL partner can offer reduced warehousing, staffing, technology, and shipping costs. Here are a few ways to lower your operating costs working with a 3PL.

- 3PLs use advanced technology to manage their operations. This allows them to use data-driven insights to provide ideas for improvement.

- 3PLs offer freight consolidation and shared warehousing, which saves money for their clients.

- 3PLs have flexible warehousing, and many provide a pay-as-you-need options.

- Transportation and logistics are the bread and butter of 3PLs, so they offer more efficiency than small in-house fulfillment teams.

- 3PLs can negotiate discounted freight rates with major parcel carriers (due to high order volumes) and pass along the cost savings to their clients.

Access to cost-saving benefits like flexible warehousing, staffing, and robust technology reduces overhead and improves the bottom line.

Save Time

Business owners understand more than most that time is money. 3PLs can help reduce the time and effort required to manage the shipping and logistics process. By leveraging the advantages of industry connections and implementing fulfillment best practices, your company will improve efficiency. Not only that, but a 3PL that utilizes multi-site distribution can decrease delivery times. Offering customers faster delivery doesn’t just improve your bottom line, but it ensures your company remains competitive.

Lastly, by partnering with a 3PL, you free up internal company time resources to focus on core competencies. Time once spent on managing fulfillment is now free to boost marketing efforts or developing new products. When a business owner isn’t in the weeds ensuring successful order fulfillment they can focus energy on what made them start the business in the first place.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, understanding the roll of Third-Party Logistics is integral to keeping up. This beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

Leveraging the advantages of a 3PL can help businesses outsource their shipping and logistics needs, freeing up valuable time and resources, thus improving their bottom line. Additionally, 3PLs can provide the peace of mind that shipments are being handled properly and efficiently, reducing the risk of delays or lost orders. Overall, using a 3PL to manage your shipping and logistics needs can greatly improve profitability. By taking advantage of their resources and expertise, businesses can save money, improve efficiency, and reduce the time and effort required to manage the shipping and logistics process.

Let Falcon Fulfillment show you how we can boost your company’s bottom line. Get in touch with one of our experts today.

Let’s Talk!

4 Ways to Maximize Your Partnership with a 3PL Company

4 Ways to Maximize Your Partnership with a 3PL Company

The success of your business depends on the strength of your partnerships. When working with a third-party logistics (3PL) company, you need to ensure that you have a solid and productive relationship. Shockingly, more than half (60-65%) of strategic partnerships fail, with common reasons including unrealistic expectations, failure to agree on objectives, and lack of trust or communication. That being said, there are several ways to bolster healthy partnerships that can stand the test of time … even endure a global pandemic. (wink, wink) Here are 4 ways to maximize your partnership with a 3PL fulfillment company

“If everyone is moving forward together, then success takes care of itself.”

Henry Ford

Create a comprehensive plan.

Before you start working with a 3PL company, you must create a comprehensive plan outlining the scope of work you intend to hire the 3PL to fulfill. This plan should include details about the services you need, when you need them, and how you expect the 3PL company to meet your expectations. It is equally important to outline goals and priorities, and service-level requirements. This will help ensure that you and the 3PL company are on the same page. Things to consider as you build your plan:

-

- Shipping frequency

- Order volumes

- Warehousing needs

- Cutoff times

- Returns management expectations

- Standardize shipping times

- Inventory management needs

- Scalability

- Expanded vendor network

Establish clear and open communication.

Effective communication is an essential component of any successful business relationship. Miscommunications and misunderstandings are breeding grounds for problems and complications. That is why it is necessary to establish clear and open dialogue between you and your 3PL to ensure both parties are in sync. Furthermore, promptly addressing questions or concerns will provide each party with the necessary support to move the partnership forward. Here are some crucial communication topics:

- Examine the contract and clarify anything ambiguous or vague.

- Discuss what kind of data needs to be shared and plan for a cadence for reporting.

- Establish how problems will be initiated, escalated, and resolved. It is important to understand communication protocols before issues arise.

- Determine if your 3PL company provides a dedicated account manager. If not, ensure you have the contact details of an individual who can assist with resolutions.

Set reasonable expectations.

Make sure that you and your 3PL are on the same page regarding what is expected of each other. 3PL companies will struggle with the same operational hurdles that you have internally. In other words, don’t set an expectation for your 3PL to solve a problem in two weeks that you haven’t been to solve for six months. However, it is entirely acceptable and healthy to share those complications initially. A solid 3PL partner could have a ready-made solution available, but you won’t know until you ask.

Another key to setting reasonable expectations is establishing what capabilities and value-added services your 3PL offers. Determine which will be included in your contract. These services could include kitting, reverse logistics, subscription box fulfillment, and specialized inventory management. Further expectations to set with your 3PL partner include; safety and security, acceptable inventory shrinkage, customer service internal/external, accuracy, and responsiveness. Confirm that expectations are realistic and achievable to ensure the best outcome for both parties.

Monitor Performance

Monitoring the performance of your 3PL is essential for ensuring that your goods are being handled correctly and that your customers are receiving their orders on time. Specifically, track performance metrics such as on-time delivery, order accuracy, cost per order, and customer satisfaction regularly to ensure that your 3PL provides the level of service you expect. Additionally, establishing benchmarks and KPIs can help you track performance and ensure that both parties get the most out of the partnership. Moreover, regular reviews and audits of the 3PL’s performance will help ensure that their services meet your expectations and that your customers receive the best possible experience.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, understanding the roll of Third-Party Logistics is integral to keeping up. This beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

These 4 ways to maximize your partnership with a 3PL company will improve your outcomes, safeguard your relationship, and help both businesses thrive. Specifically, with a comprehensive plan, additionally clear communication, moreover reasonable expectations, and furthermore regular performance monitoring, you’ll can ensure a productive and successful relationship.

Find out what partnership with Falcon Fulfillment looks like. Reach out to one of our friendly agents today.

Let’s Talk!

Best Practices to Avoid Overstocking

Best Practices to Avoid Overstocking

Have you ever had this experience? Last season your best-selling product sold out quickly because of supply chain issues and inadequate stock levels that couldn’t meet demand. You determined to avoid making the same mistake this year and ordered double the quantity. Customer trends shifted, and your best seller just became a slow-mover. Now, you are sitting on a pile of product that is not selling. Overstocking is ordering more inventory than you can sell. It can be costly and cause major headaches for business owners. It can lead to a surplus of unsold, unusable items and a loss of profits. To avoid overstocking and ensure your business’s long-term success, here are some best practices to follow:

1. Analyze your inventory data.

Analyzing your data will help you determine how much inventory you need to keep on hand and when to order more. To effectively analyze inventory data, deciding on the key metrics that require tracking and monitoring, such as sales, costs, inventory levels, and customer demand is essential. Once these metrics have been identified, the data should be organized into categories that can be easily compared, such as product type, region, period, and customer. With this data, trends, and correlations can be identified and further analyzed. Additionally, it is important to keep track of any changes to inventory or sales over time, as well as any changes in customer demand or pricing. By tracking and analyzing these data points, organizations can gain valuable insights into their inventory performance and make more informed decisions.

2. Monitor customer trends.

One of the best practices to avoid overstocking is knowing what products are trending can help you identify which items to stock and which to avoid. To do this effectively, businesses should look at customer data and feedback gathered through customer surveys, website analytics, and social media analytics. This data can be used to identify which products are popular and in demand and what kind of customer service they need. Additionally, businesses should explore emerging trends in customer buying behavior to keep up with changing customer needs and preferences. Tracking these behaviors over time and each season is crucial to avoid overstocking. Finally, businesses should use this data to create marketing campaigns and offers that target customer trends and ensure customer satisfaction.

3. Track inventory levels.

Monitor your inventory levels to ensure you always have the items your customers need. To track inventory levels effectively, companies should use a comprehensive inventory management system that tracks each item from when it is purchased to when it is sold. This should include a detailed record of all purchases, sales, and shipments. Companies should also use barcode scanners to scan and record all items entering and leaving their warehouse. Companies should also set up a system to regularly audit their inventory to ensure accuracy and identify potential issues. Finally, companies should use a reliable forecasting system to anticipate future demand and accurately plan their inventory levels. You can restock quickly and avoid overstocking if something is about to run out.

4. Utilize inventory management software.

The arduous task of inventory management can be streamlined by using technology. This best practice to avoid overstocking begins with implementing inventory management software can help you track and manage your inventory levels, eliminating a great deal of manual work. This can help you determine the right amount of stock to keep on hand and when to order more. When choosing an inventory management system, ensure they offer barcoding, inventory control, inventory tracking and reporting, alerts, and the ability to forecast. Here are a few of the industries leading inventory management programs. Each offers unique capabilities that cater to individual business needs.

5. Outsource inventory management.

If you don’t have the time or resources to manage your inventory, consider outsourcing it to a third-party supplier. Most 3PL companies can include this aspect as part of their service offering, and they have extensive experience. Partnering with a solid 3PL can allow you to focus on other aspects of your business while ensuring you always have the right amount of stock.

Taking the time to analyze your inventory data, track customer trends, and utilize inventory management software will help you make the most of your inventory and maximize your profits. By following these best practices to avoid overstocking, you’ll be able to avoid the costly problem of overstocking and ensure your business’s long-term success.

If you want to learn more about how Falcon Fulfillment can partner with you on this endeavor, chat with one of our agents today.

Let’s Talk!

How to Find a U.S. Manufacturer to Diversify Your Supply Chain

How to Find a U.S. Manufacturer to Diversify Your Supply Chain

Those without established relationships were at the mercy of an unpredictable transportation industry and gridlocked supply chain. If 2020 taught us anything, it was to diversify our supply chain to include U.S. manufacturing, if only to ensure production in an emergency. This post will discuss how to find a US manufacturer to diversify your supply chain.

Side Effects of No Preparation

Those without established relationships were at the mercy of an unpredictable transportation industry and gridlocked supply chain. If 2020 taught us anything, it was to diversify our supply chain to include U.S. manufacturing, if only to ensure production in an emergency. This post will discuss how to find a U.S. manufacturer to diversify your supply chain.

PROS of U.S. Manufacturing

- American manufacturing and labor standards are higher

- No language barrier

- Marketing appeal of being made in North America

- Easier to verify reputable manufacturers

- Faster shipping time

- High intellectual property rights protection

- Greater payment security and recourse

- American-made products are often of higher quality

- U.S. production supports the national economy

- Easier to manage quality control

CONS of U.S. Manufacturing

- Higher manufacturing costs

- Less product choice (some products are no longer manufactured in the U.S.)

Steps to find a U.S. manufacturer

This article assumes product development has already begun or is in progress with a supplier (overseas or otherwise). This means you have a viable product and know the basic requirements necessary for production. Changing to a U.S. manufacturer to diversify your supply chain is the next step. While we won’t go into detail about this aspect, it is crucial to understand the vision for your product, what type of manufacturer you require, and any special services or qualities needed in a supplier.

Step 1 – Research

Identifying a U.S. manufacturer is the first step in finding a domestic manufacturer. International supplier directories like Alibaba make it easy to discover global manufacturers. There are similar domestic directories to begin discovering local suppliers.

Online domestic directories

- ThomasNet – Has been around for 120 years and has more than 500k businesses and suppliers listed. They are one of the best places to begin looking for a U.S. manufacturer.

- Maker’s Row – This paid service helps locate manufacturers and developmental professionals to improve or refine your product offerings. Plus, they have a specific small batch option if your U.S. supplier is not your primary supplier.

- MFG – MFG is a marketplace primarily for plastic, metal, or rubberized parts production. Companies needing machining services, assembly, injection molding, metal stamping, and metal fabrication would do well to use MFG.

- Kompass – Kompass is a searchable marketplace with more than 70 countries on the site but is filterable to include online U.S. suppliers. Due to vendors ranging from lawyers and insurance agents to manufacturers and trading companies, the directory is extensive but isn’t simple to navigate. However, it is still helpful if you use the filtering mechanism well.

- Council of Manufacturing Associations Member Organizations – This is a lengthy list of sub-categorized organizations and member manufacturers in the (National Association of Manufacturers). It is a hub for news, policy, and updates for the manufacturing community. This is a good resource if you have a good idea of what type of manufacturer you are looking for.

General search engine results

You can also research manufacturers directly via Google or Safari, etc. Keep in mind most manufacturers focus on creating quality products rather than boosting their SEO performance. Therefore, you might need to scroll to the second, third, or tenth search page to find what you are looking for. Nevertheless, finding U.S. manufacturers through a search engine is still viable. Ensure you use terms like distributor, wholesale, etc., in your search to help boost your results.

Referral

A direct referral is one of the best ways to find a reputable U.S. manufacturer. Make sure to leverage your professional network to reach out and see if anyone knows of a supplier who could help you. Don’t be afraid to contact companies that potentially use a similar manufacturer and see if they wouldn’t mind sharing their contact. E.g., A shoe company specializing in fine leather would be a good source if your company produces leather handbags or backpacks.

Trade Shows

A trade show is a great place to source contacts in local manufacturing. Suppliers often attend these events to secure new buyers and showcase new capabilities. Furthermore, trade shows are a gathering of industry leaders and influencers under one roof. Finding multiple suppliers and having initial conversations at one event is possible.

Step 2 – Evaluate the shortlist

Once you have researched potential manufacturers and have a shortlist, it is time to evaluate each one. This process involves collecting information and investigating their capacity, pricing, lead times, and cultural values.

Things to consider when evaluating a potential U.S. manufacturer:

- Check certifications – Each industry will have its own specific certifications and value-specific certifications like organic, sustainably sourced, etc. If you are still determining what certifications to look for, consider researching the U.S. Consumer and Product Safety website for guidance.

- Gauge financial stability – To protect your own company, you must evaluate the financial viability of your vendors. Start by asking for a financial statement and have it reviewed by a qualified CPA. They can determine whether a supplier has adequate resources to maintain business operations.

- Asses weather-related risks – Assessing weather complications might seem silly until your manufacturer shuts down because of a hurricane for 3-6 months or longer. Ensure you know the probability of weather-related delays and have insurance should the “unthinkable” happen.

- Geographic proximity to customer base – The closer your manufacturing facility is to your customer base, the faster shipping and procurement occur and the less it costs. Therefore, it is a key factor in deciding which manufacturer to partner with.

- Scaling capability – Evaluate how flexible your supplier is with order quantities. You may find that your original choice, which offered preferential small batch order costs, cannot meet greater demand. This is why proper sales projections are crucial in determining your scalability needs.

- Contact references – Manufacturers confident in their work and service have no problem sharing references. Ask for at least 2-3 references and interview them about their experience with the supplier.

- Understand lead times and delivery success statistics – Understanding lead times and success metrics are vital to choosing the right manufacturing partner. If the potential supplier has lead times that are incongruent with your ordering cycles, it might be better to choose a different partner.

- Scrutinize payment terms – Many manufacturers will ask for full payment upfront when working with a new company. However, ask if payment terms become more flexible over time. Determine what your company needs regarding payment terms and negotiate to that end without losing the relationship.

Step 3 – Get into the nitty gritty

Once you have narrowed your shortlist and have decided to move forward with negotiating a contract with a supplier, it is time to dig into the details. There is a lot of granular work involved in finding a U.S. manufacturer diversify your supply chain. Several questions will be crucial to finding a U.S. manufacturer that will be the best fit for you.

- What is the process to ensure quality control for your product?

- What are the shipping costs?

- What are the minimum order quantities (MOQs)?

- What assurances do they offer to protect your intellectual property? Do they offer exclusivity?

- What do your clients say about you? Can you contact them?

- What will be the CPU (cost per unit)?

- What are their policies on defective products?

- Do they support sustainable and ethical production standards?

- Do they have any value-added services that would be helpful? I.e., assembly, engineering, prototyping, etc.

- What are their communication patterns, style, and platforms? Determining how you will communicate is vital to a healthy partnership and resolving issues as they arise.

While this is a partial list, it should give you a good understanding of whether or not the manufacturer will be a good fit.

Step 4 – Request a written contract

The final stage of selecting a U.S. manufacturer involves requesting a written contract outlining working together. It is best to request a proposal from a few different suppliers so that you can make the best decision for your company. Price isn’t the only contributing factor, but it will play a significant role. Therefore, it is essential to review the pricing and payment terms carefully. Ensure that all fees and timelines are clearly outlined. Once you have reviewed the contract terms and are satisfied, a partnership can begin.

A great way to find a U.S. manufacturer to diversify your supply chain, is by asking your 3PL provider. If they are anything like Falcon Fulfillment, they have solid relationships with existing suppliers with a regular cadence with the distribution facility. Furthermore, working with a quality 3PL can help to create a more resilient supply chain regardless of your manufacturing partners.

If you want to learn more about our partners and how we can help bolster your supply chain, contact one of our agents today.

Let’s Talk!

2023 E-commerce: 8 Must-Know Trends for a Successful Year

8 Must-Know E-commerce Trends for a Successful Year

It’s hard to believe it was over 27 years ago when Amazon’s first order was placed. Fast forward to today, presently the e-commerce industry has made more than $5.5. trillion in sales worldwide. As the world of e-commerce continues to evolve, it is vital for businesses to stay up-to-date on the latest trends to remain competitive. In 2022, there were significant changes in how e-commerce businesses interact with customers and how they market to them. While there are many more, our 8 must-know e-commerce trends are some of the most important ideas to be successful in the coming year.

1 – BNPL (Buy Now, Pay Later)

The number of BNPL users in the US will likely grow from 45.1 million in 2021 to 76.6 million by 2025. The BNPL model has dramatically increased the purchasing power of the American consumer. Furthermore, this flexible finance option has encouraged new growth in the lending sector with companies like; Klarna, Affirm, Afterpay and Sezzle. The buy now, pay later model has been shown to reduce cart abandonment, boost sales, speed up the checkout process, and increase the order value size. Expect an expansion of this trend as inflation rises and discretionary income wanes.

2 – Sustainability

The rise in sustainable e-commerce practices will continue to be a trend. Therefore, as Millennials and Gen-Z age into power-buying consumers, they bring an environmentally conscious mindset. According to Forbes.com, almost 30% say they want to improve the environment, with 23% wishing to reduce production waste, 22% desiring to reduce their carbon footprint, and 17% concerned with animal welfare. Therefore, to stay competitive in the e-commerce marketplace, brands are shifting product manufacturing and fulfillment to more sustainable options. One way that brands can adopt sustainable practices is by partnering with a 3PL that is environmentally conscious. Here are a few other ideas to help implement sustainability in 2023.

- Go paperless.

- Cut waste out of your manufacturing process.

- Streamline transportation routes.

- Recycle old goods.

- Source sustainable brands and products.

- Explore the rental business model.

- Use refurbished or recycled materials for in-store displays and decor.

- Reduce returns and upcycle exchanges.

3 – Social Commerce

Social commerce is where the entire shopping experience occurs on social platforms, from product discovery to purchase. According to The Future of Commerce, “Global sales via social media platforms were estimated at 992 billion U.S. dollars in 2022, and forecasts suggest that social commerce sales will reach around 2.9 trillion U.S. dollars by 2026. Social application technology has advanced to include much more than a promotional tool. Subsequently, today customers can discover new products, purchase them, and even receive customer service via social commerce. Here are some of the most relevant benefits of investing in social commerce solutions.

- Reaching customers in an age where Google has abandoned cookies, and Apple is restricting retargeting

- Keep the shopping experience native to the social platform (no need to go elsewhere to complete the sale)

- Provide a seamless and personalized shopping experience

- Cultivate community and sales 24/7

4 – Expanding Omnichannel Capabilities

Expanding the omnichannel experience for customers isn’t optional for e-commerce brands that want to remain competitive. An Aberdeen Group study showed companies that delivered solid omnichannel customer engagement retained — on average — 89 percent of their customers, compared to 33 percent for companies with weak customer engagement. Here are a few of the top ways that brands are expanding omnichannel capabilities:

- Decentralizing customer care – it’s a company-wide initiative from the CEO to the customer service representative

- Personalized experience (more on this later)

- Improving the knowledgeability of customer care staff

- Ensuring cross-channel inventory visibility with automated inventory management

- Multi-site delivery or pickup options (BOPIS)

- Provide virtual shopping experiences

- Improve the ease of making returns or exchanges

5 – Video Marketing

Video marketing is one of the best e-commerce trends for a successful year to get a jump. Why? Because video marketing is one of the most effective tools to improve customer engagement, brand loyalty, and sales. Approximately 88% of consumers have been convinced to purchase from video content. Here are a few video marketing trends to consider adding to your content arsenal this year.

- Live video – utilizing the attraction of something happening right now has proven to keep audiences engaged 3x longer than pre-recorded content and has 6x the number of engagements. Regardless of the platform used to broadcast the live content, make sure to consider adding a few to your marketing lineup.

- Search-optimized video – because videos are becoming the preferred medium of content consumption, it’s no surprise that it is essential to ensure they are showing up in relevant searches.

- Vlogs – up your brand storytelling by sharing vlogs. These can include a general overview of what your brand is about, product tutorials and overviews, as well as user-generated content.

- Silent videos – Yes, that’s right…silent videos are coming back. Many customers are scrolling social channels with the sound muted. Therefore, a video that tells a compelling story without the need for sound is performing well.

Video production doesn’t need to cost a fortune, either. Most video trends can be adopted using a simple smartphone and a few lost-cost editing tools. Even more, some editing tools are found right within the social platforms for which the video is intended. Improve your customer engagement with more video marketing this year.

6 – M-commerce

According to Statista, mobile commerce (m-commerce) accounts for 73% of the global e-commerce market. Driving this mobile commerce trend is the estimated 292 million people expected to have their own mobile devices by 2024. And it’s predicted that some 187.5 million will shop via smartphone. Therefore, while m-commerce isn’t a new trend, it continues to be a growing area of focus for e-commerce retailers. A few things m-commerce basics to ensure your company implements for 2023 to stay competitive include:

- Ultra-responsive mobile site design – Google has started to include mobile responsiveness in its search algorithm. Hence, your organic search rankings could suffer if your site is not built for mobile.

- One-click ordering – shoppers abandon carts quickly when the checkout process is too long or cumbersome. More brands are investing in streamlining the checkout process to include one-click ordering.

Shopping via mobile app – many brands are driving consumers to a mobile app built for buying. 85% of users prefer a mobile shopping app to a mobile-responsive website. Plus, mobile apps are converting sales at a whopping 157% more.

7 – Personalization

Personalization is using personal data to provide tailored experiences to shoppers of products in a retail environment. Whereas every path to purchase is different, and personalization in retail aims to serve each individual based on their needs and behaviors. Even though personalization has been part of the e-commerce conversation for more than five years now, it remains a relevant trend in 2023. Here are some specific personalization trends to adopt in 2023.

- Leveraging AI/Machine learning to provide nuanced personalization for each customer

- Implementing “Zero-Party Data” mining

- Location-based marketing and geotargeted sales, promotions, and discounts

- Personalized loyalty programs

- Security and data-privacy improvements

8 – Using AI/Machine Learning

AI, or artificial intelligence, can mean many things, but when it comes to e-commerce it includes; machine learning, predictive analytics, and advanced AI that can convert troves of data into actionable insights. Ultimately, the utilization of AI is a must-know e-commerce trend for a successful year more than ever. AI can be most helpful for retailers in a few key areas. They are:

- Interactive Chatbots – As customer service becomes a trend that will soon be a primary differentiator, chatbots powered by AI will be a tool that improves customer satisfaction and can perform routine requests 24/7 without the need for human resources.

- Dynamic Marketing Outreach – Advanced CRM systems are learning customers’ behaviors and preferences to create a detailed shopper profile and utilize this information to deliver proactive and personalized outbound marketing — tailored recommendations, rewards, or content.

- Operational AI – programs can preemptively manage orders, staffing, and inventory levels and predict sales cycles. This technology streamlines operational processes and improves efficiency.

- Personalization – AI can help offer a unique shopping experience to all customers, making recommendations, rewards, and discounts based on consumer preferences and behaviors.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, understanding the roll of Third-Party Logistics is integral to keeping up. This beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

By staying up-to-date on the latest e-commerce trends for a successful year, businesses can ensure that they remain competitive in the evolving world of e-commerce. Chiefly, by leveraging these 8 must-know e-commerce trends, businesses can create an engaging, personalized shopping experience for their customers and build their brand. Furthermore, if you are overwhelmed by all that needs to be done in your business, let Falcon handle your order fulfillment.

We can help expand your omnichannel offering and free you up to focus on implementing the trends that will best serve your business success in 2023. Get in touch with one of our agents today.

Let’s Talk!

Dunnage - What it is and why you need it

Dunnage – What it is and why you need it

Protecting items during shipping is crucial to ensure they arrive undamaged. Statistics show that 20% of consumers return items because the consumers received damaged products. Use the right mix of dunnage to satisfy consumers’ growing expectations and to safeguard your financial investment. Working with a fulfillment partner expert in shipping, packing, and returns will help you determine what types to use. Let’s uncover what dunnage is and why you need it.

What is dunnage?

Dunnage is the packing material that protects items during shipping and handling. Dunnage isn’t a common word consumers know, but it is an integral part of fulfillment. Companies spend a lot of money and time deciding what type and quantity of materials you need for products to arrive safely at their intended destination. Dunnage can include packing peanuts, bubble wrap, paper, and even wooden crates affixed to large items and appliances.

Why dunnage is used in shipping?

- To prevent damage – the main reason is to avoid damaging the shipped item. Imagine sending an antique vase from Europe in a box without bubble wrap, paper fill, or packing peanuts. It is not likely that the vase would arrive in one piece.

- To keep items dry – another reason dunnage is used in shipping is to keep the product from getting wet. Packages moving from shipping containers, warehouses, and trucks are often exposed to the elements. Therefore, dunnage ensures that the product doesn’t arrive in a soggy mess, even if the outer box gets wet.

- Shock absorption – parcels get dropped, pushed, bounced, and pressed during transport. Dunnage helps to absorb the vibration and minimize the jostling of the product in the package.

What types of dunnage are there?

Solid dunnage materials.

Solid dunnage materials are used for heavy, highly valuable, or oversized items. The type or combinations of materials used depends on the product material, shape, size, and shipping container. However, there are a few common solid materials used in shipping.

Wood

Wood is a heavyweight material. It is readily available, and it is a renewable resource. However, many ports and countries impose additional customs duties on wood dunnage, and others will not allow it all because of foreign pest concerns.

Solid Plastics

Solid plastic dunnage is one of the best materials for high-value goods, heavy items, or oddly shaped products. You can form it into any shape and it is made of high-density polyethylene (HDPE). This type of material is expensive compared to other options but is worth the investment when you consider the replacement costs of high-value items and large machinery.

Steel

People use steel for another solid option when shipping heavy goods or partitioning items within a single container. This type of dunnage is expensive, so you typically use it for high-value goods.

Soft dunnage materials.

People use soft dunnage when shipping lightweight and smaller items. People often use a combination of solid and soft when shipping freight. For example, a supplier might send a pallet of electronics using solid plastic pallets, containing each item in corrugated cardboard, bubble wrap, and shrink-wrapped. Consider the size, shape, material, and value of the products shipped when deciding which type of dunnage best safeguards them in transit.

Bubble Wrap

Bubble wrap isn’t just your child’s favorite popping toy but also a favorite in the shipping industry. This dunnage is inexpensive and does a great job protecting fragile items like glass and china. You can also reuse bubble wrap many times, provided you haven’t popped the bubbles!

Air Pillows

Air pillows are an excellent solution, especially to fill gaps in a package. You primarily use these to create barriers to keep a product from shifting or sliding during transport. They are lightweight, so they don’t add much to the shipping costs.

Foam

People often use foam to safeguard electronics or other items that have sharp edges. It also pads sharp, fragile, or sensitive things like medical supplies.

Kraft Paper

Kraft paper is a great option because it is a renewable resource, cheap, and works. You often find items that require strength and durability packed in kraft paper. If you have ever received an item packed in crinkled paper, this was kraft paper packaging.

Corrugated Paper

Corrugated paper is one of the best and most commonly used forms of dunnage. Its high-tech construction allows it to carry a variety of weights, and it is excellent for keeping items dry and wicking away moisture.

Custom Dunnage

Some products require a custom solution. Working with a dunnage provider for a custom solution might be necessary. Alternatively, you want a custom packaging solution that includes branded packaging and creates a memorable unboxing experience. Falcon Fulfillment specializes in this.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, therefore understanding the roll of Third-Party Logistics is integral to keeping up. In light of this our beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

3PL fulfillment companies are experts in protecting items during shipping. No matter whether you ship forklifts or champagne flutes, you will use dunnage to protect those items. If you want to learn more about how partnering with Falcon Fulfillment can help you select the best packaging options for your business, get in touch today.

Let’s Talk!