Common Mistakes to Avoid When Creating a 3PL RFP

Common Mistakes to Avoid When Creating a 3PL RFP

E-commerce brands seeking scalable order fulfillment often issue RFPs (Requests for Proposal) to assess potential 3PL (Third-Party Logistics) partners. But faulty RFP processes lead many retailers to select the wrong fulfillment provider, resulting in headaches that sabotage growth.

What crucial errors must e-commerce companies avoid when creating 3PL RFPs to choose a fulfillment partner able to scale in tandem with sales trajectories? This definitive guide covers the 8 most common mistakes brands make when creating RFPs for selecting 3PL partners, and how to steer clear of them.

Rushing the 3PL RFP Process

Scrambling brands often hastily create RFPs seeking quick fixes to fulfillment fires. But rushed RFPs overlook critical diligence, leading to misaligned partnerships. Allocate ample time for strategic development, even if interim measures are required.

Casting Too Wide a Net

Don’t spread efforts thin by approaching countless prospects. Thoroughly vet providers first to narrow the field to five or less specialized 3PLs warranting closer inspection. This filtering allows more strategic dialogue to avoid mistakes when making a RFP for a 3PL.

Excluding Business Vision & Outlook

While outlining functional requirements, 56% of RFPs neglect furnishing context on business objectives, growth plans and vision for the ideal partnership. This big picture perspective allows prospects to better evaluate long-term synergy.

Supplying Incomplete Operational Statistics

Accurate historical volumes, peaks, inventory detail and more enable prospective 3PLs to build pricing models sans speculative assumptions that can necessitate future escalations. Supply robust intelligence upfront.

Prioritizing Low Cost Above All

Lean too narrow on obtaining the rock bottom rate and risk alignment gaps that undermine customer loyalty and retention. Conduct balanced assessments weighing cost, projected growth impact, and satisfaction enablement.

Discounting Future-Proofing Needs

Another great way to avoid mistakes when making a 3PL RFP is to rigorously assess each prospect’s ability to seamlessly scale, adapt and flex in sync with explosive growth without declines in service quality or necessitating migration downtime and restarts.

Minimizing Data & Analytics Factors

Ceding control of operations makes order visibility and decision-driving analytics essential. Scrutinize and compare intelligence functionality and transparency across all contenders.

Disregarding Automation Investment

Evaluate and compare process automation capabilities across providers. Heavily manual operations will struggle with efficiently accommodating growth. Favor significant technology investors.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, understanding the roll of Third-Party Logistics is integral to keeping up. This beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

Brands can make big mistakes when putting together RFPs to find a 3PL fulfillment partner. They focus too much on getting the cheapest price. Or they don’t think about what they will need in the future. This causes problems later on.

How should brands avoiding RFP mistakes when searching for a 3PL? They should look at all the important things, not just price:

Make sure the 3PL can grow as fast as your business grows, make sure the 3PL has good technology to manage orders accurately, make sure the 3PL shares reports to help you manage your business, make sure the 3PL has experience with businesses like yours.

Overall, by looking at all these things, not just price, you can find the right 3PL partner. Without a doubt this helps your business do well for a long time without needing to switch 3PLs again and again. Picking the wrong partner is painful! Do your research upfront to find the best match.

Looking for a fulfillment solution? Submit an RPF to Falcon and we will get you the best options available.

Let’s Talk!

E-commerce Fulfillment Infrastructure that Scales

E-commerce Fulfillment Infrastructure that Scales

As an e-commerce business owner you are well aware of the ups and downs that coming with running a successful company. When you first launch a business you can get by with manual effort and a small team, however as you scale systems, processes, and thoughtful partners are needed to grow. In this article we are going to cover five key elements of e-commerce fulfillment infrastructure that scales as you grow.

Warehousing

Warehousing is the physical space where inventory is stored and distributed for e-commerce fulfillment. Ample storage space is a crucial component in fulfillment infrastructure that will scale. The importance of good warehousing cannot be understated. It facilitates efficient inventory management. Adequate space allows easier and faster inventory intake, storage, and order fulfillment. It provides enough room for a clean and organized stock room where products are easier counted and found as orders are received. Alternatively, inventory management becomes cramped, chaotic, and ineffective when a company lacks warehouse space. Deficient warehouse space increases the risk of stock damage, inventory shrinkage, and incorrect product reporting. As a result, customer experience is threatened.

Inventory Management Systems

Inventory management plays a significant role in meeting and exceeding customer expectations. Businesses can keep track of their inventory levels and orders in real-time. Many inventory management systems integrate with standard POS systems. It is possible to track inventory manually, but it isn’t scalable. To build a fulfillment infrastructure that scales, it is necessary to invest in an inventory management system that has the following capabilities:

- Lot and serial tracking

- Shipping and Receiving

- Barcoding and Scanning

- Label Generation

- Mobile Accessibility

- Reporting Capabilities

While these features should be available in most inventory management systems, also consider your needs. Do you want to automate inventory management processes? Do you need a Saas program or on-premise, or both? Regardless of which system you select, ensure that it will meet your current needs and provide expansion possibilities.

Shipping Platforms

Logistics or shipping platforms have become widely used by businesses of all sizes because they offer vital insight and cost savings. Online shipping platforms are used to compare shipping rates, label printing and tracking services, and other logistics services. They can help meet ever-growing customer demands, boost revenue growth, and help to stay competitive. Implementing an advanced shipping system can help you find the right carrier service at the lowest cost. Additional benefits include: streamlining transportation by leveraging zone skipping, managing compliance issues, tracking and resolving delivery problems in real-time, and helping make data-informed decisions with ease.

Payment Processors

These platforms facilitate online payments from customers, such as credit cards and online banking services. Basically a payment processor is a mediator between the merchant and the bank by managing credit card transactions. It validates and authorizes payments by ensuring that the buyer has enough funds and that the card they use is valid for transferring the funds into the seller’s account. Additional benefits of using a quality payment processor:

- Allows retailers to accept debit and credit card transactions

- Offers alternative payment methods like PayPal or Apple Pay

- Integrates with your POS systems

- Ensures customer payments are properly validated

Every e-commerce business will need a solid payment processor and an integrated payment gateway to capture sales and refunds when necessary.

Returns and Refunds Management

Returns management, also known as reverse logistics, involves the same steps as “forward” logistics and therefore requires similar processes. Therefore, investing in returns management systems allows businesses to seamlessly process returns and refunds, including tracking and communication with customers regarding their orders. Handling returns well improves overall customer satisfaction, provides for faster turnaround, reduces waste, and can improve profitability.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, understanding the roll of Third-Party Logistics is integral to keeping up. This beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

Build E-commerce Fulfillment Infrastructure that Scales with a 3PL

Almost all of the systems and infrastructure pieces mentioned above are available through a quality 3PL partner. Not only can a 3PL provide ample warehousing, but they often allow flexibility in scaling up and down with storage, so you only pay for what you need. Additionally, a 3PL typically offers high-tech inventory management systems that include barcoding, WMS, shipping, and receiving. A fulfillment company like Falcon Fulfillment will leverage the most advanced shipping processing to reduce costs, expedite deliveries, and ensure proper labeling and compliance. Your business could also benefit from a more comprehensive network of carriers and lower shipping costs due to volume discounts. Similarly, even returns management can be bundled into your 3PL logistics offering.

Building e-commerce fulfillment infrastructure that scales becomes exponentially easier when partnering with a solid 3PL. If you want to spend more of your valuable time building and growing your business and less time managing the logistics, let Falcon Fulfillment help. Find out if we are a good fit today.

Let’s Talk!

The Impact of Trump’s Tariffs on Costs, Choices, and Strategies

The global supply chain is facing a significant shift as the Trump administration’s new tariffs take effect. These policies, intended to boost domestic manufacturing, have triggered disruptions across industries, affecting costs, availability, and logistics strategies. Businesses relying on international sourcing must now rethink their supply chain management to maintain competitiveness in a rapidly changing environment.

The Rising Costs of Imports and Supply Chain Adjustments

One of the most immediate consequences of the Trump Tariffs Impact is the increase in costs for imported goods. Higher import duties on materials like steel, aluminum, and electronic components have driven up production expenses, forcing businesses to seek alternative sourcing solutions.

Companies involved in third-party logistics (3PL), freight forwarding, and order fulfillment solutions are experiencing increased operational costs, which ultimately trickle down to consumers. Additionally, businesses that rely on multi-channel fulfillment and e-commerce fulfillment are particularly vulnerable to these changes, as supply chain delays and price fluctuations create uncertainty in shipping and delivery timelines.

Fewer Choices for Consumers and Retailers

Another critical aspect of the Trump Tariffs Impact is the reduction in product variety. With tariffs making imports more expensive, businesses are being forced to cut back on international inventory, limiting consumer choices. For example, companies utilizing inventory management systems to track and optimize stock levels are now restructuring their product offerings based on cost efficiency rather than consumer demand.

This shift is particularly evident in industries that rely on vendor-managed inventory (VMI) and supply chain optimization to maintain just-in-time delivery models. With rising costs, some businesses are transitioning toward bulk shipping and freight consolidation to maximize efficiency while reducing expenses. However, these strategies come with trade-offs, including longer lead times and potential inventory shortages.

Strategic Responses: Nearshoring and Supply Chain Diversification

To counteract the Trump Tariffs Impact, companies are increasingly turning to nearshoring and supply chain diversification. Many businesses are moving production closer to home, leveraging warehousing and distribution centers in Mexico, Canada, and other neighboring countries to reduce dependency on China and other tariff-affected regions.

Furthermore, cross-docking and reverse logistics are gaining traction as companies attempt to minimize costs while optimizing transportation routes. Some are investing in fulfillment center expansions in domestic markets, ensuring a more resilient supply chain structure.

How Logistics Companies Are Adapting

Logistics providers and fulfillment services are at the forefront of these changes. To remain competitive, they are implementing warehouse automation and integrating inventory tracking software to streamline operations. Additionally, carrier selection and management strategies are evolving, with businesses negotiating better freight rates to offset increased costs.

The Role of Technology in Mitigating Tariff Challenges

Technology is playing a crucial role in helping businesses navigate the Trump Tariffs Impact. The use of cloud-based warehouse management systems (WMS) and transportation management systems (TMS) is increasing, allowing companies to optimize order fulfillment metrics and reporting for better decision-making.

Additionally, investments in order tracking and management are helping businesses maintain transparency with customers despite delays in same-day and next-day delivery services. These advancements are crucial in sustaining consumer trust and operational efficiency amid ongoing supply chain disruptions.

International Trade and Customs Brokerage Challenges

With tariffs reshaping international trade, businesses engaged in international shipping and import/export are facing new compliance hurdles. The complexity of customs brokerage processes has increased, leading to potential delays and higher administrative costs. To navigate these challenges, companies are leaning on fulfillment cost analysis and freight audit and payment services to track financial impacts and optimize their shipping strategies.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, therefore understanding the roll of Third-Party Logistics is integral to keeping up. In light of this our beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

Preparing for the Future: A New Era of Supply Chain Management

As businesses continue to adapt to the Trump Tariffs Impact, the importance of strategic planning and supply chain agility cannot be overstated. Companies investing in demand planning, outbound and inbound logistics, and shipment consolidation will be better positioned to mitigate risks and sustain profitability in a shifting global trade environment

While tariffs present significant challenges, they also offer an opportunity for businesses to rethink their supply chain strategies, embrace new technologies, and strengthen their logistics networks. Those that proactively adjust will not only weather the storm but emerge stronger in an increasingly complex and competitive market.

Let’s Talk!

80/20 Inventory Management Rule

80/20 Inventory Management Rule

Determining how to prioritize inventory for maximum profits can take some trial and error. However, a mathematical theory has been successfully applied to multiple industries. It is known as the 80/20 rule. The rule suggests that 80% of results come from 20% of causes. In the case of inventory, it typically shows that 80% of profits come from 20% of products sold. Therefore, the primary purpose of implementing the 80/20 inventory management rule is to maximize profits. Let’s understand what it is, its advantages and drawbacks, and how to implement it.

80/20 Rule Definition and History

Italian economist Vilfredo Pareto first discovered the Pareto Principle in the early 1900s. He observed that 80% of the land was owned by 20% of the population. The principle states that 80% of effects are derived from 20% of causes. Pareto originally applied the principle in the area of economics. The nature of the 80/20 rule is a power distribution law that can be used in many circumstances. It’s super cool, consistent, and profit-boosting math. The rule demonstrates that 80% of sales come from 20% of clients.

Advantages of using the 80/20 inventory management rule

When the principle is effectively applied to inventory management, it can help maximize profitability and increase inventory efficiency. You’ll increase sales when you accurately identify top performers and emphasize them over slower sellers. If you further sort to favor higher-margin products within that 20%, you optimize your inventory for both volume and profitability.

Drawbacks of the 80/20 inventory management rule

The main drawback of using the 80/20 inventory management rule is that it can obscure up-and-coming products that haven’t YET broken into the top 20% category. This is why it is essential to evaluate items against trend reports. Reviewing the products gaining traction will help keep future best sellers in the system long enough to prove their value.

Steps to implement the 80/20 inventory management rule

Integrate and utilize an inventory management system

A system of tracking inventory and sales is required to generate accurate reports of top sellers. The more high-tech your system, the more detail you can generate. Small business owners can run manual inventory reports so long as it is consistent in the type and timeframe. As SKUs and sales increase, implementing an automated inventory management system becomes crucial to success. Here are 7 types of inventory reports that can help implement the 80/20 inventory management rule.

- Inventory performance report – includes sales performance hierarchy as well as year-over-year growth.

- Inventory profitability report – includes SKU profitability, listing profitability, and trending profitability.

- Inventory value report – a quick snapshot of the value of goods stored in your warehouse; this report’s modifications can determine product performance, sitting age, and inventory turnover ratios.

- Stock level report – includes critical levels to determine reordering patterns and prevent stockouts.

- Inventory forecasting report – includes estimates of future sales based on historical data within a set timeframe.

- Sales report – includes a holistic approach to revenue generated from each sales channel, customer, and product vertical.

- Cost of goods sold (COGS) report – helps determine the bottom line on each product, necessary to identify the most profitable products.

Identify 20% of top sellers

To determine the top sellers in your inventory, firstly you must decide what to track and which reports will give you the most accurate picture. At a minimum, it is necessary to consider the following data points:

ABC is a popular method to categorize inventory. Simply put, it is a way to prioritize product performance into three distinct buckets. Using the ABC method helps determine your top sellers’ popularity and profitability.

- A items: Top 20% of your products that result in 70% of sales

- B items: Middle 30% of your products that result in 20% of sales

- C items: Bottom 50% of your products that result in 10% of sales

Refine mid-level performers

Once you discover your top performers, some products will be in the mid-level range. Specifically these are your “B category products” and can include your trending products. This information highlights an opportunity to explore how to make them profitable and change marketing efforts. If modifications don’t move them forward, then it might be time to sunset.

Sunset slow or underperforming products

Once you have tiered your inventory according to profitability and performance, it is time to sunset or liquidate deadstock. Products that are taking up valuable storage space and are slow-moving despite efforts to modify marketing or sales efforts should be liquidated to free up capital for more profitable products. Letting go of slow-moving or deadstock can be difficult, but keeping a healthy bottom line is essential.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, therefore understanding the roll of Third-Party Logistics is integral to keeping up. In light of this our beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

Retail and e-commerce business owners implementing data-driven methodologies like the 80/20 inventory management rule stand a better chance of success. Their decisions are not based on gut instinct, reacting to customer demand, or marketing trends but on statistical analysis, and the numbers don’t lie. If you want to learn more about how Falcon Fulfillment can help boost profitability and implement the 80/20 rule, get in touch with one of our specialists today.

If you’re ready to start the transition or have questions, contact us to learn more about our services.

Let’s Talk!

Bubble Wrap Appreciation Day

Bubble Wrap Appreciation Day

Bubble wrap is more than just a packaging protector – it’s also a beloved toy for both kids and adults! Additionally, the popping is uniquely satisfying and even soothing. Bubble Wrap Appreciation Day allows us to reconnect with the simple pleasures of plastic bubbles.

A Brief History of Bubble Wrap

Furthermore, bubble wrap was invented in 1957 by engineers Alfred Fielding and Marc Chavannes, originally as a textured wallpaper. But it failed as a decoration and they soon realized its superior protective qualities as packaging material.

Sealed Air Corporation now manufactures Bubble Wrap brand bubble cushioning. The term “bubble wrap” has become a generic trademark for the material. Many brands produce the air-filled wrap, but Bubble Wrap remains the best known.

The first commercial bubble wrap was introduced in 1960 for industrial shipping use. Later adopted widely by e-commerce companies to protect goods in transit, this indispensable packaging material is now a ubiquitous presence.

Why We Love Bubble Wrap

There’s just something immensely pleasing about bubble wrap’s look and feel. The orderly rows of encapsulated bubbles beg you to squeeze them pop by pop. And who can resist?

Popping bubble wrap bubbles triggers a little burst of accomplishment. It’s instant stress relief and satisfaction. The tactile experience provides an outlet for nervous energy or frustration.

Beyond its functional protecting and cushioning use, bubble wrap has become a beloved fidget toy for kids and adults alike. Its versatile appeal makes it a superior desk accessory for distraction and amusement.

Celebrating Bubble Wrap Appreciation Day

Bubble Wrap Appreciation Day allows us to take a moment to enjoy this simple sensory pleasure.

First celebrated in 2001 in Bloomington, Indiana, the holiday commemorates the day a local radio station accidentally broadcast the sound of popping bubble wrap on air. But the satisfactions of bubble wrap have long been discovered by anyone who’s handled those plastic pillows of air.

Here are some fun ways to observe this special day:

Bubble Wrap Popping Parties

Gather co-workers, family, or friends to see who can create the loudest pops or continously pop the longest strip of bubbles. Provide prizes for most bubbles popped!

DIY Bubble Wrap Furniture

Furthermore, temporarily cover chairs or small tables in bubble wrap secured with painter’s tape. Protect surfaces from adhesive residue. Now you have a poppable place to sit or set your coffee mug!

Bubble Wrap Stress Balls

Additionally, fill zippered bubble wrap sleeves with rice, beans, or air and securely seal. Knead and squeeze these portable stress relievers anytime you need to decompress.

Bubble Wrap Fashion

Moreover, design bracelets, necklaces, rings, or other jewelry fashioned from bubble wrap strips glued or taped into accessories. The bubbles add texture and provide stress relief you can wear!

Popping Playlists

Furthermore, create the perfect bubble wrapping popping soundtrack with upbeat songs about bubbles and popping like “Pop Goes the World” by Men Without Hats and “Bubbly” by Colbie Caillat.

Appreciating Bubble Wrap Every Day

Set aside a few minutes from your busy day for some bubble wrap appreciation. Order some bubble wrap rolls from an online retailer so you’ll always have it on hand.

Moreover, keep a stash in your desk drawer at the office for bubble wrap fidgeting breaks. Share strips with co-workers who seem like they need to decompress.

Additionally, add a sheet to a friend’s package or hide some in a birthday card for fun hidden nostalgia.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, therefore understanding the roll of Third-Party Logistics is integral to keeping up. In light of this our beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

However you choose to enjoy it, bubble wrap popping provides simple, inexpensive amusement. Rediscover small sensory pleasures with Bubble Wrap Appreciation Day!

Need Bubble Wrap help? Falcon is your Bubble Wrap ExpertTM!!

Let’s Talk!

Making Returns Easy - 4 Ways to Streamline Returns Management

Making Returns Easy

A seamless return process helps increase customer satisfaction and retention, and minimize the negative impact they have on your business. Returns happen for various reasons, including; unmet expectations, damaged or defective products, and incorrect fit. Surprisingly, last year, an average of 8.1% of all purchased products were returned. The returns management process, or reverse logistics, involves customer service, inventory management, and shipping logistics. It requires intentional planning, clear communication, and staying customer focused. Here are some of the key aspects of making returns easy.

Communication

Simplifying and making returns trouble-free boils down to communication. Communication is at the center of straightforward returns, whether it is communicating with customers or updating internal staff and protocols.

Communicating with customers

The main focus of your returns management process should be to make your customer’s life easy. When a customer is dissatisfied with a purchase, making the process to return the item can save the relationship and even win a brand advocate. Firstly, start by outlining the process for shipping a product back and requesting a repair, refund, or exchange. Then set expected timelines for each aspect of the returns process. Customers want regular updates on the status of their return and how long it will take to resolve it. Over-communicate with customers throughout the returns process. This builds trust and confidence in your brand. Clear and consistent communication can lead to the purchaser returning to your company despite a poor buying experience.

Streamline Internal Communication

Not only do your customers need regular updates, but so do the staff that will receive the product, evaluate it, and adds them back into the inventory system when possible. Invest in developing a system of internal communications so that when items arrive at your warehouse, they don’t overwhelm staff or clutter your storage area. A centralized method to receive, evaluate, and update inventory systems will ensure a seamless process. A few crucial parts of the internal returns process include:

- The customer requests a return, and internal teams either approve or disapprove the request.

- Approved requests will receive logistics instructions to return the item to the company.

- The product is received in the warehouse.

- Staff determines if the product can be resold or need to be discarded, liquidated, or destroyed.

- Depending on protocols for the product, staff approves a refund, packages a replacement product, and ships it.

- Products that can be resold are added back into the inventory management system and restocked

Returns Automation

One of the best ways to make returns effortless is to automate the returns management process. This includes implementing customer portals to begin the returns process without speaking with a customer service team. Furthermore, most aspects of communication with customers can be automated. There are several robust returns management software systems available. Here are a few of the highly reviewed options.

In addition to utilizing an automation software program, you can partner with your fulfillment teams to streamline the returns process. At Falcon Fulfillment, we specialize in e-commerce returns management. Working with a 3PL you trust can ease concerns about the returns process and help boost customer satisfaction. Plus, most 3PL companies already have a streamlined, efficient returns system refined over time with hundreds of returns. In other words, they have the expertise to do it right.

Integrated Technology

Integrating your POS systems with inventory management and returns management creates a streamlined process. Getting all the systems and software platforms to communicate with one another can be tricky. As you evaluate and set up your technology, ensure that integrations are “straightforward.”

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, therefore understanding the roll of Third-Party Logistics is integral to keeping up. In light of this our beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

While avoiding returns altogether isn’t always possible, it is possible to make the process easy. Ensure you have intentionally created a seamless process for your customers. Remember that making their life easy is the most crucial aspect of returns. If a customer has a good experience with getting a refund, replacement, or credit, they will be more likely to shop with your business again. If they have a poor product experience and a difficult return process, you have lost them for good and will likely also have to deal with poor customer reviews. Partnering with a 3PL specializing in returns management is another option when implementing a new returns process.

Get in touch today if you want to learn more about how Falcon Fulfillment can help with your returns.

Let’s Talk!

Things to Consider When Switching 3PL Providers

Things to Consider When Switching 3PL Providers

If you’re a business owner considering switching 3PL fulfillment providers, then you’re likely well aware of the many benefits of outsourcing your order fulfillment. Working with a third-party logistics (3PL) provider can streamline your business operations and reduce labor costs while providing customers with a better overall experience.

However, with so many 3PL fulfillment providers, knowing which is right for your business can take time and effort. To that end, here are some things to consider when you’re deciding whether or not to switch 3PL fulfillment providers.

Evaluate Your Current Provider

It’s important to take a close look at your fulfillment provider. Specifically, are they meeting your needs in terms of service, cost, and reliability? If not, it may be time to look for a new provider. Here are seven questions to ask when reviewing your fulfillment partner.

- Are they meeting accuracy and on-time delivery expectations?

- What services are included in your fulfillment package, and are they meeting/exceeding your business needs?

- Are the fees you are paying in line with industry standards?

- How accurate and transparent is the reporting for tracking inventory and orders?

- Are they handling returns and refunds?

- On a scale of 1-10 (10 being excellent), how is the communication between you and consumers?

- Do they have the ability to scale with plans you have for the future?

Research Potential Providers

Once you’ve identified potential providers, it’s time to do research. Read reviews and testimonials from other businesses that have used their services, comparing rates and solutions. If you don’t know where to begin, you might want to start with WarehousingAndFulfillment.com. This free service matches your specific business needs to more than 500 prescreened 3PL companies.

In addition, to super charge your search, you should prepare and submit RFP’s (Request For Proposal) to a few new providers. This will let you see what other companies you have targeted have to offer and if they are a good fit for you. Don’t know how to create an effective RFP? Check out our guide on common mistakes to avoid here.

Consider Your Customers’ Needs

Your customers should be your top priority. Chiefly, think about how the new provider will impact their experience. Could they receive their orders faster? Are there more choices for delivery? Do they provide better packaging and protection for parcels? What are the unique problems you are trying to solve in your supply chain and fulfillment needs? Contemplate the solutions you will be looking for in a new partner. Here are some common customer pain points that can be alleviated by working with a 3PL partner.

- Long lead times that result in stockouts

- Slow delivery timelines

- Lack of tracking and delivery communication

- Difficulty in making a return or exchange

- Items arriving damaged

- Disconnected inventory management systems that result in inaccurate stock counts (leading to customer frustration at the POS)

Ask Questions

Before making a decision, make sure to ask any questions you may have about the services offered by the potential provider. Here are ten questions to get your creative juices flowing:

- What is your experience in omnichannel fulfillment? In other words, will your technology integrate across my sales channels?

- What kind of automation do you implement within your warehouses?

- What other technologies do you use to streamline operations?

- How do you handle receiving from vendors? Will I be required to palletize or barcode my inventory before arrival?

- How do you handle lost inventory or incorrect orders?

- How are your fees structured? Do I get charged for individual services like; kitting, picking, packing, and shipping or do you offer an all-inclusive option?

- What are your product specialties?

- Is there a minimum monthly order volume required to work with your organization?

- Do you offer same-day order processing?

- What kind of accuracy guarantee can I expect?

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, therefore understanding the roll of Third-Party Logistics is integral to keeping up. In light of this our beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

Switching 3PL fulfillment providers can be daunting, but it is often necessary to ensure that your business is getting the best possible service. Not all 3PL companies are created equal. Take time to evaluate your current provider, research potential providers, and always keep your customers’ needs in mind. You can improve your operations and provide a superior customer experience with the right 3PL provider.

Falcon Fulfillment are expert in logistics, supply chain management, and e-commerce fulfillment. We have worked with brands in the beauty, pet, and home goods industries, among many others. Our dedicated account managers make communication between your company and fulfillment teams seamless. We don’t work with clients just because they meet our criteria; we partner with them. When our customers win, we win.

Find out how partnering with Falcon can help your company streamline fulfillment and exceed customer expectations. Reach out to one of our agents today.

Let’s Talk!

Global Impact of Trump Trade Review on Supply Chains

Where We Are At

The recent announcement of the Trump trade review has caught the attention of businesses worldwide. Indeed, many companies were initially anxious about the possibility of steep tariffs on goods coming from China, Mexico, and Canada. However, the administration’s decision to delay immediate levies and instead focus on a thorough investigation has offered a brief reprieve. Nevertheless, the global supply chain is already responding to the possibility that new trade rules could be around the corner. Consequently, stakeholders in Third-Party Logistics (3PL), Fulfillment Services, and Warehousing and Distribution must remain vigilant. Therefore, understanding the implications of the Trump trade review becomes more critical than ever. In this blog, we will explore how this evolving situation might affect industries ranging from Order Fulfillment Solutions to E-commerce Fulfillment, and how businesses can prepare accordingly.

Understanding the Trump Trade Review

Above all, the Trump trade review aims to assess trade deficits, currency manipulation, and the balance of trade agreements with key partners. The review includes countries like China, Mexico, and Canada, which are integral to the United States’ Supply Chain Management network. This assessment could lead to policy changes designed to protect domestic industries. However, such measures might pose challenges for companies reliant on cross-border trade. Although the final outcome is uncertain, businesses should start evaluating potential shifts in Inventory Management, Shipping and Delivery practices, and even Last-Mile Delivery solutions. Furthermore, policymakers are emphasizing a more methodical approach, which may leave time for supply chain actors to adapt.

Potential Impact on Third-Party Logistics (3PL) and Supply Chain Management

First and foremost, Third-Party Logistics (3PL) providers depend heavily on streamlined cross-border operations. Consequently, any change in tariffs or trade regulations following the Trump trade review could disrupt the efficiency of Freight Forwarding, Cross-Docking, and other logistics processes. In addition, Reverse Logistics may be affected by any new mandates, as returning goods could become more complicated under stricter rules. Moreover, providers specializing in Bulk Shipping might find that altered trade agreements introduce additional paperwork or cost. Indeed, 3PL companies that proactively optimize routes and implement Supply Chain Optimization strategies will be best positioned to navigate a turbulent marketplace.

Effects on Warehousing, Distribution, and Fulfillment Services

Undoubtedly, Warehousing and Distribution centers are vital hubs that facilitate Order Fulfillment Solutions. If new tariffs or trade terms arise from the Trump trade review, the cost of holding and moving inventory could increase. For instance, Vendor-Managed Inventory (VMI) models might be pressured by higher import costs, spurring adjustments in stocking levels. Consequently, businesses may need to bolster their Order Tracking and Management capabilities to stay ahead of compliance hurdles. Additionally, providers of Fulfillment Services will likely need to invest in technology, staff training, and new strategies to remain competitive under evolving trade policies. Therefore, a robust alignment with supply chain partners could mitigate potential risks.

Navigating Cross-Border Complexities

International commerce is intricate under normal circumstances. As a result, if the Trump trade review influences regulations, cross-border shipments could face delays or additional levies. This heightened complexity may prompt more reliance on Customs Brokerage to ensure accurate declarations and tariffs. Similarly, companies might explore Dropshipping Solutions or alternate International Shipping and Import/Export routes to bypass potential bottlenecks. For many, Multi-Channel Fulfillment strategies will become crucial, helping to distribute stock more evenly and minimize customs challenges. For instance, Kitting and Assembly performed in a local Fulfillment Center could reduce cross-border friction and enhance overall flexibility

Adapting Order Fulfillment Solutions and E-commerce Fulfillment

Equally important is the impact on E-commerce Fulfillment. With online sales skyrocketing, rapid deliveries are a top priority. However, new trade requirements might slow down the flow of products, ultimately affecting Warehouse Automation timelines and Transportation Management System (TMS) setups. Indeed, speed is the name of the game in online retail, so any delays caused by new tariffs or customs protocols could harm customer satisfaction. As a result, e-commerce companies should examine their Order Accuracy and Quality Control measures, ensuring smooth operations even if political or economic changes occur. Moreover, investing in Inventory Tracking Software becomes more essential, particularly if businesses must quickly adjust to new sourcing or distribution requirements.

Ensuring Smooth Shipping and Delivery

Timely Shipping and Delivery hinges on several integrated processes. Though the Trump trade review has postponed immediate tariffs, shipping lanes may still be subject to sudden adjustments. In fact, unforeseen fees or border inspections could arise if the review ultimately leads to trade barriers. Therefore, companies must evaluate their Safety and Security Measures in Warehousing to guarantee that goods move safely across borders. Moreover, advanced 3PL Technology Solutions offer real-time visibility into shipments, aiding in Carrier Selection and Management. For instance, businesses can leverage Packaging Optimization to reduce dimensional weight charges, or engage in Freight Rate Negotiation to secure more favorable terms. Overall, adaptability will be the hallmark of success in this climate.

Monitoring Inventory Management and Reverse Logistics

Another area that could be heavily influenced by the Trump trade review is Inventory Management—specifically with regard to Freight Audit and Payment Services and Inventory Forecasting. Indeed, if tariffs rise or trade becomes more restrictive, planning for stock levels will become more complex. Therefore, Reverse Logistics strategies might also change, as products returned from international customers could incur additional fees. It is important to track metrics such as Order Fulfillment Metrics and Reporting and to explore Scalable Fulfillment Solutions that can rapidly adjust to fluctuations in demand or supply routes. Furthermore, efficient Return Merchandise Authorization (RMA) Processing can prevent disruptions that stem from evolving trade practices. Keeping an eye on On-Time Delivery statistics is also essential, because unexpected border checks could lead to higher costs and unsatisfied customers.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, therefore understanding the roll of Third-Party Logistics is integral to keeping up. In light of this our beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

the Trump trade review serves as a reminder that global trade can shift rapidly, affecting businesses of all sizes. Many anticipate that policy changes, if they come, will affect everything from Inventory Cycle Counts to Cloud-Based Warehouse Management System (WMS) functionalities. Consequently, organizations must be vigilant, adopting a proactive stance that includes Demand Planning, Outbound and Inbound Logistics adjustments, and even Order Splitting and Routing. By embracing robust Fulfillment Cost Analysis and staying informed about potential shifts, companies can weather the uncertainties ahead.

Ultimately, whether you are a large multinational or a small business exploring FBA models, thorough preparation and strategic planning will be paramount. Indeed, by staying agile and leveraging modern supply chain technologies, organizations can turn potential disruptions into opportunities for growth in the face of evolving trade policies.

Let’s Talk!

9 Easy Ways to Thank Customers

9 Easy Ways to Thank Customers

Every business owner is thankful for their customers. Without them, the company ceases to exist. Businesses that actively thank their customers and show appreciation build loyal customers and stand to be more profitable than those that consider gratefulness an afterthought. Research shows that 68% of customers change brands because of “perceived indifference.” Having a quality product isn’t enough to build a loyal customer base. Businesses need to show a little love and care for the people responsible for keeping the company running! It is important to understand the benefits of thanking customers and selecting a few appreciation strategies to implement if you haven’t already! Here are 9 easy ways to thank customers.

Revolve your world around the customer, and more customers will revolve around you.

Heather Williams

Why thanking customers is essential!

Going above and beyond to thank customers cannot be undervalued. Here are the main reasons a business should implement a customer appreciation strategy.

- It helps build strong customer relationships and trust

- Increases retention

- Creates brand advocates

- Boosts long-term customer value

Easy Ways to Thank Customers

Offer expertise and education for free

Companies that readily share their expertise show their customers they want them to get the most out of their purchases. Sharing articles, posts, and videos with customers that help educate and equip them is customer appreciation gold! For example, if your business sells hand-poured candles. Share articles explaining how to get the most-even burn, reuse the candle container, or which scents are best for which moods. These things help customers love your product more and show that you don’t stop at the point of sale. Another excellent customer appreciation idea for a company that sells small appliances would be sending out reminders and informative emails to maintain the product, i.e., cleaning the filters.

Give back to the community

Nothing says you care more than supporting and getting involved in your community. Investing your time or resources to cause(s) your customers love shows you aren’t just out to get their money. The most successful example where this idea works is when the cause relates to the product or service the business offers. For example, a pet company that sells dog toys and gear donates 10% of its annual revenue to a local rescue shelter.

We make a living by what we get, but we make a life by what we give.

Winston Churchill

Create a personalized “thank you” video

With new AI technology, you could create a general thank you video with a code-based moment(s) where someone’s name is inserted. Before you think this is entirely unrealistic, consider the “Elf Yourself” videos! Here’s a sample script:

“Hey {Name},

Thank you so much for your recent {Brand name} purchase. We love what we do and know you will love your {product name}. You are the reason we do what we do. We would love to see you in action. Post a pic or video {wearing, using, etc.} and make sure to tag us!”

While this could take a little upfront design and planning, it makes the thank you more personal and fun! Customers love both.

Create a memorable unboxing experience

When a branded box arrives, it has a greater impact on consumer brand awareness. The customer gets the sense that your business cares deeply about your products arriving safely. Creating a memorable unboxing experience helps your brand tell its story in a way that drives customer loyalty.

Send thoughtful gifts

The key here is to ensure the gifts are thoughtful. Sending a branded pen is not an ideal representation of your business unless you sell paper goods. If that is the case, make sure the pen is extraordinary. The main idea around sending a thoughtful gift is to include something that is either personalized or practical. Some good examples of thoughtful gifts would be a travel-size hand cream included with the purchase of other skin care products. How about adding a glasses repair kit with a sunglass purchase? How about leather conditioner included when someone purchases a new handbag? Make sure to let your customers know they are a “bonus” so they don’t assume they came as part of the package.

Create a customer loyalty program

Rewarding your most loyal customers is always a good idea. The consumers who love your brand will share it even more, when they are recognized or rewarded for coming back repeatedly. According to Shopify, as many as 84% of consumers say they’re more apt to stick with a brand that offers a loyalty program. And 66% of consumers say the ability to earn rewards changes their spending behavior. A million ways exist to develop a loyalty program, but the main idea is to keep your customers happy and engaged. Try a few different strategies and see what works well.

Handwritten notes

Handwritten notes are one of the easiest ways to show appreciation to customers. It isn’t expensive, and it doesn’t take a lot of effort to throw in a handwritten note. It might be challenging at scale, but creating thoughtful notes that rotate within orders can make a difference. You can even pay to have a robot handwrite your thoughts and send the cards! Check these 25 examples of thank you note messages that can be easily modified for your business.

Host Giveaways

Everyone loves a good giveaway. Create a giveaway for previous customers and potential new customers. These are especially effective when they involve new product releases or high-value items. Allowing previous customers to have extra entries is another way to say thank you. Just be aware of “giveaway rules” that vary by state, so you don’t inadvertently get yourself in legal hot water.

Showcase a customer of the month

An easy way to thank your customers is to showcase them. Whether you share a remarkable story via email marketing or on your social channels, highlighting why you appreciate a customer is special. Not only will the customer being featured love it, but others will also see that you notice when a customer is exceptionally loyal, patient, or kind. You can use any criteria relevant to your industry to select your customer. Keep in mind that some may not want to participate because of privacy. You can use an alias for your uber private consumers.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, therefore understanding the roll of Third-Party Logistics is integral to keeping up. In light of this our beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

There are many easy ways to thank your customers, but the most important thing is to do it! No matter how you decide to show appreciation, keep the customer at the center of your gratitude. Create a strategy that is personalized and practical. By implementing thankfulness, you will build stronger relationships and trust and increase long-term customer value. Ultimately, being a grateful company will translate to a healthier bottom line.

Falcon Fulfillment is in the business of helping companies get products into their customer’s hands, but to do it with the highest level of excellence. We can help include personalized notes with our kitting services, and we specialize in branded packaging options.

Get in touch with one of our specialists today, and thank you for being here. We are grateful to have the chance to serve your company!

Let’s Talk!

Calculating Ending Inventory - What you need to know

What is ending inventory?

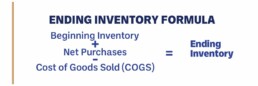

Determining the amount of stock left at the end of a sales cycle is important. Ending inventory, sometimes called closing inventory, is the total value of unsold goods at the end of an accounting period. This valuation provides insight into assets, gross profit, pricing, ordering, and production. The simplest formula for calculating ending inventory is to add net purchases to your beginning inventory and subtract the cost of goods sold.

Why calculating ending inventory is necessary.

Calculating ending inventory is vital to know how much you are selling and for how much. It is also a key aspect of the accounting process because it directly affects your balance sheet and tax burden. Here are some reasons why getting your ending inventory valuations right is essential:

- Verifies recorded inventory matches, actual physical inventory counts

- Highlights inventory shrinkage issues due to human error, theft, or other reasons.

- Reveals how much revenue you are making on what you are selling.

- Minimizes overstock by providing accurate inventory counts.

- Delivers excellent insight and control over stock-related and financial decisions

- Impacts gross and net profits as well as tax liabilities.

- Allows investors and financial institutions to evaluate for funding events

- Selecting the best method and staying consistent with that method will provide insight into the health and profitability of the company.

Selecting the best method to calculate your ending inventory and staying with that method is imperative to minimize accounting errors and meet company needs. The choice can affect the stated value of the company’s assets, profit, and tax liability. Before filing your income or end-of-year taxes, it is necessary to calculate your ending inventory correctly.

What are the different methods to calculate ending inventory?

Knowing your ending inventory gives you insight into how to make necessary business decisions related to stock, finances, and even fulfillment needs. Here are a few standard methods to calculate ending inventory.

FIFO method (first in, first out)

FIFO is a valuation method that assumes the first purchased inventory was sold first. The COGS (cost of goods sold during the period) is based on the stock bought earliest in the accounting period. This approach is suitable for many companies because it follows common operations strategies where older items are sold to make room for newer goods. This method is commonly used during an inflationary period. However, it can produce lower COGS and higher gross profits. This calculation often results in higher income tax burdens for the period.

LIFO method (last in, first out)

LIFO is another valuation method that assumes the most recently purchased goods are the first to be sold. This method closely reflects the actual cost of replacing the current inventory. It is typically used during periods of increasing prices. Companies can report higher COGS and lower gross profits, reducing the tax liability during the period. A significant drawback of this method is that it is rarely accepted outside of the US because it is not allowed under International Financial Reporting Standards (IFRS).

WAC method (weighted average cost)

The weighted average cost method (WAC) is where a business average all inventory costs to calculate COGS and ending inventory. Calculate it by dividing the total amount you spent on your inventory by the total number of items.

Here is a simple example. Let’s say you started your fiscal year with an inventory balance of 1000 items at $3.00 each. You purchased an additional 500 items at $3.50 later in the accounting period. Your ending inventory would include 1500 items valued at $3.17 each, totaling $4,750.

This method is the simplest way to evaluate ending inventory; it is best suited for companies that sell similar products. As businesses expand their product offering, calculating ending inventory becomes more complex.

Gross profit method

The gross profit method estimates ending inventory where an actual physical count is not desired or necessary. This method uses the company’s expected gross profit margin for the current period as a starting point for estimating COGS and ending inventory. Companies will use their historical gross profit margin as a guideline for their current expected gross margin. Keep in mind that this method is not acceptable for audited financial statements.

Here are the steps to calculate gross profit:

- Multiply the net sales during the current period by (1 – expected gross profit margin) to obtain an estimate of COGS.

- Apply the standard inventory valuation formula: Add up the period’s beginning inventory and the cost of all further inventory purchases to date. Then, subtract the estimated COGS to obtain the ending inventory.

Retail method

This method is best for retail stores looking to estimate inventory counts for a specific timeframe without doing a physical count. It uses the cost-to-retail ratio.

Total Cost Of Goods For Sale / Retail Value Of Those Goods = Cost-To-Retail Ratio

Once you have the cost-to-retail ratio, you multiply this number by the net sales for the period to estimate COGS. Then you plug this amount into the standing ending inventory formula listed above. This is an imprecise count but is helpful to assess ending inventory until a more accurate method can be performed for accounting and tax purposes.

How partnering with a 3PL can help with inventory management.

A 3PL provider can help with inventory management in several ways. First, they can provide warehousing and fulfillment services, which involve storing inventory, packaging, and shipping orders. They can perform physical stock counts when needed. They can also help track inventory, which is essential for keeping accurate records and preventing out-of-stock or overstocked situations.

In addition, a 3PL can help with inventory forecasting, which involves predicting future demand for products. Overall, a 3PL can be an excellent asset for any business that needs help with inventory management. By outsourcing complex inventory tracking and management task, companies can save time and money while improving customer service and satisfaction.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, therefore understanding the roll of Third-Party Logistics is integral to keeping up. In light of this our beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

Because inventory directly affects your business’s balance sheet and income, it is necessary to choose a method that aligns with business needs and operations workflows. Whether you manage inventory in-house or outsource it to a 3PL partner, calculating accurate ending inventory is an essential metric for your business.

If you want to learn more about how Falcon Fulfillment can become your inventory management partner, get in touch with one of our agents today.

Let’s Talk!