Ways to Reduce Inventory Shrinkage

What is inventory shrinkage? How does it affect your bottom line? What is an acceptable percentage of inventory shrinkage? How can I prevent it?

Inventory shrinkage occurs when the physical inventory levels do not match the accounting records. The accounting data says you should have a specific number of physical products available, but after an actual count, a difference exists. No matter the inventory management systems or processes you have in place, shrinkage will occur.

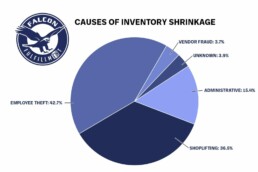

Many reasons cause shrinkage, from human errors to theft. Inventory shrinkage affects retailers’ bottom line. According to the National Retail Security Survey, inventory shrinkage accounted for 1.38% of all retail sales. This represents a significant loss of revenue for retailers and e-commerce businesses. This article will discuss the leading causes of inventory shrinkage, how to calculate it, and ways to reduce shrinkage.

Causes of Inventory Shrinkage

Employee Theft

Employee theft accounts for nearly 42.7% of all inventory shrinkage. Whether from a brick-and-mortar shop or the warehouse, human beings are the most significant threat to increasing inventory shrinkage. Petty theft is stealing something that doesn’t have a high value. Taking a few pens, copy paper, or a coffee mug from the office isn’t a big deal, right? It becomes a big deal when you have 300 employees doing the same thing. Bolder employees find ways to steal much higher ticket items.

Skimming fraud is another form of theft that is much more challenging to detect. Employees pocket cash payments without ever adding the transaction to the system. This is where regular audits come in handy. Whether your staff is committing petty theft or skimming fraud, all forms of employee theft will adversely affect your bottom line.

Shoplifting

The ugly step-cousin of employee theft is consumer theft. Shoplifting has become a greater risk in the post-pandemic era due to staffing shortages across all retail outlets. The U.S. Chamber of Commerce discovered that employees quitting retail are only outpaced by the Leisure and Hospitality industries. Currently, less staff are responsible for managing more square footage in almost every retail outlet. According to a report released by the Council on Criminal Justice, shoplifting accounts for the largest portion of thefts next to motor vehicles. With less staff, it means fewer eyes watching and profiling potential shoplifters.

Administrative

Human error is another cause of inventory shrinkage. Albeit less than employee theft, it is still significant. Reporting errors, data input errors, and problems reconciling the accounts contribute to administrative inventory shrinkage.

Vendor Fraud

Vendor fraud occurs when the vendor or manufacturer sends a different amount of inventory than is stated on the invoice. This is relatively easy to spot when you only receive 10-20 boxes in a shipment. It becomes almost impossible when your shipments are 100s of packages.

Lost Shipments

Misplaced goods or lost shipments are another one of the most common causes of inventory shrinkage. Busy distribution and fulfillment centers are loading and unloading thousands of parcels a day. Warehouse crews move pallets from receiving to their warehousing space quickly to make room for the next shipment. Most shipments receive proper barcodes and are stored properly. However, some packages loose their barcode, are mislabeled, or are improperly stored. That package is lost.

Reducing Inventory Shrinkage

In fiscal year 2020, over 15% of retailers in the United States stated that they experienced an inventory shrink of 3% and higher.

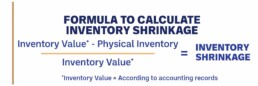

Calculate Inventory Shrinkage Rate

Before reducing your shrinkage, you need to know how to calculate it. The acceptable level of shrinkage is less than 1%, but many companies experience much higher levels. Here is the industry formula for calculating your inventory shrinkage rate.

One of the major contributors to reducing inventory shrinkage is simply measuring it. You cannot fix what you don’t know is a problem! Once you have a baseline rate, you can implement the following processes to measure accurately and reduce inventory shrinkage effectively.

Track Every Item – Barcode and SKU

Every product must possess a unique identifier. This empowers inventory management systems to effectively track in real-time. It furnishes the data to promptly pinpoint inventory shrinkage and gain insight into where products are losing or getting stolen. Many fulfillment companies and suppliers have the capability to attach unique barcodes or SKUs to products before or during the receiving process. This decreases human error and enhances the capability to track inventory as it progresses through the sales process.

Train Employees

Certainly, you will instruct your employees in performing their duties, but it’s essential to provide targeted training on employee theft. Establish a clear policy and procedure concerning theft. Clearly define the repercussions for theft and its detrimental impact on the company. Introduce a mechanism for employees to anonymously report suspected theft. Clearly communicate what constitutes theft and the threshold at which termination or legal action will be pursued. Ensure that all employees grasp the expected standards.

Use Automated Inventory Management Systems

Having a single point of truth regarding inventory levels is key to reducing inventory shrinkage. Managing all available products through a uniform system ensures accurate and up-to-date data. Administrative errors are reduced when information is not transferred from one system to another. Barcodes and SKUs have the exact details in North Dakota as they do in the warehouse in Salt Lake City. Automated inventory management systems unify the data across the fulfillment and final sales exchange.

Enhanced Security Measures

Because so much inventory shrinkage is attributed to theft, increasing security measures is an excellent way to reduce it. Install cameras throughout your retail space, behind the cash register, store room, and loading dock to prevent theft. Give each employee a unique login to track voided cash transactions and irregular sales patterns. Also, consider hiring a security guard, especially for high-value items or when you notice an increase in theft in a specific area. Don’t forget about your warehouse or distribution locations. If you outsource fulfillment, ensure your partner has 24/7 security, cameras, and a regular schedule of reviewing employees.

Surprise Audits and Consistent Tracking

Surprise! Checking your inventory levels regularly and unexpectedly helps reduce inventory shrinkage. Surprise audits minimize theft and highlight admin errors regularly. When you commit to periodically updating inventory levels in real-time, you will identify the main issues, and you can begin to reduce the impact.

Partner with an Excellent 3PL

Partnering with an excellent 3PL can provide your business with many of the solutions listed here. They leverage automated inventory management systems that can provide real-time stock levels. They invest in serious security measures, including cameras, on-site security, and thorough employee training. Furthermore, a great 3PL can help implement barcoding for every SKU that syncs to the IMS. Their receiving crews are trained with double-check systems to reduce lost or misplaced products. Lastly, vendor fraud is minimized by providing accurate and detailed receiving reports. Working with Falcon Fulfillment would be a great option!

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, therefore understanding the roll of Third-Party Logistics is integral to keeping up. In light of this our beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

Inventory shrinkage is an unfortunate reality, but it can be managed. At Falcon Fulfillment, we understand that every dollar counts when growing and building a business.

Want to learn more ways to reduce inventory shrinkage for your company? Get in touch today.

Let’s Talk!