D2C Beer Shipping

D2C Beer Shipping

If you thought crafting the most delicious brew was challenging, wait until you delve into the complexities of direct-to-consumer or D2C beer shipping. Brewmasters everywhere are pondering the untapped potential that delivering directly to customers offers. However, beer shipping proves to be as intricate as the diverse taste profiles of beer consumers. Given that beer, along with all alcohol, falls under restricted domestic items, fulfilling orders across state lines necessitates an expert-level grasp of compliance. Nevertheless, despite these challenges, beer enthusiasts nationwide crave access to their favorite brews delivered to their doorsteps. In this article, we will explore how Falcon Fulfillment can alleviate the hurdles associated with direct-to-consumer beer shipping.

What is D2C Beer Shipping?

Direct-to-consumer beer shipping (D2C) is the shipping of any type of alcohol directly to the purchaser through delivery by a third-party carrier (UPS or FedEx, etc). In D2C fulfillment, the producer makes the sale straight to the customer, who receives the order shipped to their home or other personal address. To meet compliance standards, a producer must abide by the laws and requirements of the state they ship into, which often includes getting licensed and paying taxes on their shipments. If you are curious, consumer-to-consumer beer shipping is illegal.

Complications of D2C Beer Shipping

Limited States Allow D2C Beer Shipping

Only eleven states plus D.C. permit D2C beer shipping. This is a serious limitation, especially in comparison with the wine industry. D2C beer shipping is available to 14.8% of the (21+) population compared with 96.7% available to wine consumers. The legislation surrounding shipping beer is positioned to change thanks to the COVID-19 pandemic. Beer drinkers in both California and New York have revived interest in changing the prohibition-style laws surrounding beer delivery to consumers. This gives many brewers hope that they will soon have access to a broader beer-drinking audience.

Maintaining Interstate Compliance is Difficult

Every state has different laws surrounding the D2C beer shipping regulations. Even within the eleven states that allow it, there are nuances that must be observed in order to continue to maintain proper licensure. Both the producers and the shipper must have the appropriate licenses in order to ship beer. Not only that but every shipment that contains alcohol must be documented for tracking and tax purposes. Most producers partner with an approved carrier in order to alleviate some of the headaches of maintaining compliance. This leads us to why using Falcon Fulfillment for your D2C beer shipping can help.

Advantages of Partnering with Falcon Fulfillment for D2C Beer Shipping

Maintain a Quality Product

From maintaining temperature thresholds to ensuring expedited processing for your suds, Falcon can streamline order processing. This speed and accuracy keep your product fresh for your consumers. Falcon offers flexibility to modify warehouse staging spaces for promotions and ongoing quick-turnaround product sales. Furthermore, they can provide fast transport from the brewery to the distribution location via temperature-controlled FTL. We understand that certain types of fulfillment like D2C beer shipping require extra care to ensure a quality product arrives at your customer’s front door.

Boost Your Brewery Bottom Line

Starting a D2C beer shipping revenue model helps to increase your customer base, build recurring revenue, and satisfy your existing consumers. Not only that but shipping directly to consumers gives your brewery higher margins than wholesale or retail options. Most brewmasters rely on taprooms to get their suds in the hands of their fans. However, the average cost of building and kitting out a taproom is nearly $500k. Bringing the bar to your customer’s home is one of the most affordable ways to increase your bottom line without the capital investment of a bar or taproom.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, therefore understanding the roll of Third-Party Logistics is integral to keeping up. In light of this our beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

Even though the D2C beer shipping market still has significant restrictions, many craft brewers have not yet entered this field. From our distribution center in Kentucky, we can help launch your D2C beer shipping model and satisfy your fans across the U.S.

If you want to find out more about how get in touch with Falcon today.

Let’s Talk!

4 Ways a 3PL Can Help With Outsourcing Inventory Management

4 Ways a 3PL Can Help With Outsourcing Inventory Management

According to Investopedia, inventory management is the process of ordering, storing, using, and selling a company’s raw materials, components, and finished products. Inventory management requires significant resources in order to run it efficiently. Inventory is one of the most valuable components of a business; therefore, mismanaging it can be detrimental to the organization’s success. Proficient inventory management streamlines the process of reducing overages and stockouts. If your company is losing time and money due to inefficiencies or staff overload, it is probably time to outsource inventory management to a third party. There are several ways a 3PL can help with outsourcing inventory management.

Aspects of Inventory Management

Why would I outsource inventory management?

- You need to improve efficiency.

- You need more time to focus on core competencies.

- You no longer have the warehouse space to contain adequate inventory to scale.

- You need to improve margins on shipping and staffing.

Ways a 3PL Can Help With Inventory Management

Provide Flexible Storage

Many growing e-commerce businesses work out of their basements, garages, and attics when they launch. Eventually, these spaces are inadequate to ensure quick, organized, and streamlined fulfillment. If you’re fulfilling in-house, you may be experiencing these types of growing pains. Alternatively, if you’ve rented a warehouse, it might be an expensive overhead cost. The jumbled mess of packaging, bubble wrap, and returns can become someone else’s problem. Partnering with a 3PL can give you flexible warehousing space depending on fluctuations in sales and seasonal needs. You can scale your warehousing resources quickly.

Faster and Cheaper Order Fulfillment

A 3PL provides expert order fulfillment services. Your business can benefit from bulk discounts by accessing their expertise and broad national network of facilities. Partnering with a 3PL allows your business to leverage economies of scale and negotiate lower shipping and delivery charges. Additionally, your company will likely see an expedited order delivery timeframe. A 3PL fulfillment team can receive an order, package it, and get it out for delivery in a single day. Provided your 3PL has multi-site distribution, you can offer 2-day delivery almost anywhere in the US. Fast delivery times make your company more competitive in the cut-throat e-commerce landscape. Outsourcing this aspect of inventory management is a life-saver.

Advanced Inventory Management Software

Because inventory management and transparency are critical to running a successful 3PL, most use highly advanced technology. This is another cost savings because you do not have to spend money to purchase software or train staff to use it. Your business will be able to use top-of-the-line technology and receive training on how to utilize it to grow your business. The detailed reporting available includes; stock levels, automated inventory tasks, forecasting, and returns management. Here are some benefits of using an automated inventory management system, such as the one Falcon Fulfillment uses.

Reduce Inventory and Fulfillment Staff

As your business grows, you will naturally require more staff in order to fulfill orders. If you have been running a business for more than five minutes, you understand that people are a company’s most valuable and expensive asset. The more you can reduce your inventory and fulfillment staffing risk, the more you can focus on core competencies. When you partner with a 3PL, the stress of whether or not your warehouse staff will show up and get your orders out the door is eliminated. Furthermore, you do not have to bear the expense and risk of injuries from fulfillment staff. When you work with a premiere 3PL like Falcon Fulfillment, you have even greater assurance that your inventory management teams are well-cared for.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, therefore understanding the roll of Third-Party Logistics is integral to keeping up. In light of this our beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

While we have only discussed four ways a 3PL can help with outsourcing inventory management, there are many more. A 3PL can save you money from reducing shipping costs to staffing. The most valuable resource any entrepreneur has is time. Outsourcing your inventory management to a 3PL gives you back a little more of this precious commodity. With more time, you can focus on what your business does best and leave the inventory and fulfillment piece to the experts!

Are you interested in learning more about how Falcon’s proprietary inventory management software could help your business? Get in touch today.

Let’s Talk!

Rail vs. Road Transportation: The Differences

Rail vs. Road Transportation: Key Differences for Efficient Shipping

Rail and road transportation stand as titans in the logistics realm, each offering unique advantages for shipping goods. When seeking efficiency and cost-effectiveness, deciphering between these two modes becomes pivotal. Let’s take a drive into the intricacies of rail vs. road transportation to unravel the optimal choice for your shipping needs.

Rail Transport: Unveiling the Dynamics

Rail transport, inherently reliant on dedicated tracks, emerges as a resilient mode for long-distance shipping. Additionally, it relies on specialized freight trains, strategically engineered to efficiently transport significant cargo volumes across extensive networks that stretch across continents and nations.

Advantages of Rail Transport:

1. Economies of Scale:

Freight trains capitalize on economies of scale, leveraging their ability to carry enormous loads per trip. This scalability translates into a cost advantage, particularly for long-haul shipments.

2. Environmental Sustainability:

Embracing rail transport contributes to environmental conservation. Its reduced carbon footprint per ton-mile compared to road transport aligns with eco-friendly logistics solutions.

3. Reliability in Long-Hauls:

For time-insensitive shipments, rail excels in reliability, delivering cargo without being significantly affected by external factors that often impede road transport.

Road Transport: The Wheels of Localized Logistics

In contrast, road transport maneuvers goods using trucks, catering adeptly to localized logistics, especially for shorter distances within a country’s boundaries.

Advantages of Road Transport:

1. Door-to-Door Service:

A distinct edge for road transport lies in its capability to offer door-to-door service, providing flexibility and convenience that rail transport might lack.

2. Time-Sensitive Deliveries:

Trucks excel in ensuring timely deliveries, especially for time-sensitive cargo, thanks to their ability to navigate through shorter distances swiftly.

3. Flexibility in Schedules:

Unlike rail, road transport grants the flexibility to tailor schedules according to specific delivery requests, accommodating varying logistical needs.

Comprehensive Analysis of Key Differences

When comparing rail and road transportation, there are important differences to consider. These differences affect things like cost, distance covered, how long it takes to deliver goods, safety, flexibility, and how much can be transported. Understanding these differences is important for making smart choices about how to move things from one place to another. It helps in planning the best way to get things where they need to go, making sure it’s done efficiently and smoothly.

1. Cost Consideration:

Rail transportation triumphs in cost-effectiveness for long distances, leveraging its capacity and reduced fuel consumption.

Conversely, road transport’s cost efficiency shines on shorter routes, often with lower shipping charges and adaptable pricing structures.

2. Distances Covered:

Rail thrives on long-haul routes due to its ability to transport larger volumes across extensive networks.

Roads cater effectively to shorter distances and offer more direct routes with a door-to-door service.

3. Transit Time:

Road transport typically ensures quicker transit due to its agility and flexibility in navigating through various terrains.

Rail transport, while having longer transit times, provides predictability and reliability not hampered by external factors.

4. Safety Measures:

Road transport is more susceptible to accidents due to factors like traffic congestion, weather conditions, and human errors.

Rail transport, with fewer accidents, boasts enhanced cargo safety through fewer handling instances.

5. Flexibility and Customization:

Roads grant flexibility in scheduling and customizing routes to meet specific delivery demands.

Rail operates on stringent preplanned schedules, limiting customization but ensuring adherence to timelines.

6. Capacity and Coverage:

Trucks have significant weight-bearing capacities, but rail haulage triumphs with its capability to move substantial cargo volumes in a single trip.

Rail networks have limitations in coverage compared to roads, necessitating intermodal transportation for comprehensive door-to-door service.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, understanding the roll of Third-Party Logistics is integral to keeping up. This beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

Deciding the Optimal Choice

In navigating the labyrinth of logistics, the choice between rail and road transportation hinges upon various factors such as cost, timeframe, cargo volume, destination, and specific requirements.

Understanding the nuances between these two modes empowers informed decision-making, enabling businesses to tailor their transportation strategies for optimal efficiency, cost-effectiveness, and timely deliveries.

The decision you make today between rail and road transportation lays the tracks for your logistics efficiency tomorrow. Embrace these differences wisely to steer your cargo towards a journey marked by efficiency and punctuality.

Let’s Talk!

Proven Strategies to Increase Your Average Order Value

Increasing your average order value (AOV) is a key metric for any e-commerce business looking to maximize revenue and grow their brand. AOV represents the average amount spent each time a customer places an order on your website. By implementing effective strategies to increase AOV, you can generate more revenue without necessarily acquiring new customers.

How Do We Calculate AOV?

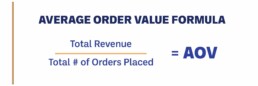

Before we discuss ways to change our AOV we need to define it. Here is the formula to calculate your own AOV.

The AOV Formula

To calculate your average order value, use the following formula:

AOV = Total Revenue ÷ Number of Orders

For example, if your monthly revenue is $50,000 and you processed 1,000 orders, your AOV would be:

AOV = $50,000 ÷ 1,000

AOV = $50

Tracking your AOV over time will help you gauge the effectiveness of your efforts to increase it.

Let’s explore five proven strategies to boost your AOV and discuss how partnering with a third-party logistics (3PL) provider can help you achieve your goals.

Offer Free Shipping Thresholds

One of the most effective ways to increase AOV is by offering free shipping thresholds. Encourage customers to spend more by setting a minimum order value to qualify for free shipping. For example, “Spend $50 or more to get free shipping.” This incentivizes customers to add more items to their cart to reach the threshold, thereby increasing your AOV.

Create Product Bundles

Product bundling is another powerful strategy to increase AOV. By grouping complementary products together and offering them at a slightly discounted price, you encourage customers to purchase more items in a single order. This not only boosts your AOV but also provides value to your customers by offering them a curated selection of products.

Implement Cross-Selling and Upselling

Cross-selling involves suggesting related or complementary products to customers during their shopping journey, while upselling encourages customers to choose a higher-priced version of the product they’re interested in. Implement these techniques on your product pages, in the shopping cart, and during the checkout process to increase the likelihood of customers adding more items to their order.

Launch a Customer Loyalty Program

Rewarding loyal customers is a great way to increase AOV over time. Implement a loyalty program that offers points, discounts, or exclusive perks for repeat purchases. This not only encourages customers to shop with you more frequently but also incentivizes them to spend more per order to earn those rewards.

Provide Limited-Time Offers and Promotions

Creating a sense of urgency can be highly effective in increasing AOV. Offer limited-time promotions, such as flash sales or seasonal discounts, to encourage customers to make larger purchases. You can also provide bundle deals or gift with purchase promotions to incentivize higher order values.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, therefore understanding the roll of Third-Party Logistics is integral to keeping up. In light of this our beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

Increasing your average order value is a critical component of growing your e-commerce business. By implementing strategies such as offering free shipping thresholds, creating product bundles, implementing cross-selling and upselling, launching a loyalty program, and providing limited-time promotions, you can encourage your customers to spend more per order. Partnering with a 3PL provider can further support your efforts to increase AOV by offering faster shipping options, optimizing your inventory management, and streamlining your order fulfillment process. By focusing on increasing your AOV and leveraging the expertise of a 3PL, you can unlock new growth opportunities for your e-commerce business and take your brand to the next level.

Interested in learning more about ways we can help you scale? Get in touch with one of our team today.

Let’s Talk!

Inventory Costs Explained and Mistakes to Avoid

Inventory Costs Explained and Mistakes to Avoid

Inventory costs are one of the assets and liabilities a company has on its balance sheet. Managing inventory costs is crucial for success. Managing inventory is a complex process that involves multiple vendors, suppliers, fees, and reports. Striking the delicate balance of ordering and storing the right amount of inventory is tricky. Companies don’t want to under-order but they don’t want to over-order. Establishing what to track and when to make adjustments can confuse companies. This article will explain the main inventory costs and common mistakes companies should avoid when creating an inventory management process.

Inventory Costs Explained – Categories

What are the main costs associated with inventory? There are four primary categories of expenses related to inventory management.

Purchasing Costs

Purchasing costs are the price paid to a supplier or vendor for a product. If you purchase 100 vintage-style handbags at $15 per item, your purchase cost is $1500. This line item does not include shipping, handling, taxes, or insurance. Some companies calculate the purchase cost within the ordering cost category. It depends on personal preference and the level of detail you desire.

Ordering Costs

Ordering costs typically encompass labor, fees, and transportation involved in shipping your product from the manufacturer to your storage facility. Although these expenses typically represent minor amounts compared to purchase costs, inaccurate measurement can lead to their rapid accumulation.

Carrying Costs

Carrying costs, also known as “holding costs,” refer to fees associated with maintaining inventory in stock. This category encompasses various expenses, ranging from employee wages to warehouse rents. Carrying costs vary significantly depending on the type of product being sold and managed. Particularly, products with a limited shelf-life or requiring consistent handling, movement, and restocking tend to incur higher expenses.

Stockout Costs

Stockout costs encompass any expenses related to revenue loss due to inventory shortages. These costs can accumulate for various reasons, such as failing to update your in-store or online inventory management system before running out of a product. When a customer purchases an unavailable product, it triggers a refund process, potentially resulting in a lost sale if a suitable alternative cannot be offered. Additionally, stockouts lead to lost sales, as many consumers turn to competitors when a product is listed as “out-of-stock,” representing a missed opportunity cost. Fortunately, many of these expenses can be avoided or minimized. Companies can increase their supply chain resilience by partnering with a competent 3PL.

Inventory Costs Explained – What to Track

Storage Costs

Storage costs include repetitive payments related to inventory storage management. These include warehouse rents, heating and cooling costs, lighting, security, and employee wages. Any fee for maintaining a clean, organized, and pest-free space would be considered a storage cost. Holding onto inventory that is slow-moving or considered deadstock increases storage costs quickly.

Capital Costs

Capital costs are typically the largest upfront investment regarding inventory costs. They are a one-time fee required to physically store and carry inventory to the designated storage facility. Capital costs can include land purchases, building or buying a warehouse, and sourcing inventory equipment (e.g., forklifts, pallets, storage racks/shelves, etc.).

Damage & Obsolescence

Tracking inventory costs closely is crucial as items often get banged, bruised, and battered during the shipping and receiving process. Recognizing patterns of damage enables corrective action; otherwise, it’s akin to wasting money. Similarly, obsolete items represent money left on the shelf, as businesses continue to bear the costs of unsold and outdated products on their balance sheets.

Theft and Fraud

Solving theft and fraud related to inventory costs necessitates meticulous tracking and the use of precise inventory management systems. While it won’t catch every criminal that threatens the bottom line, it will undoubtedly show where items are going missing.

Taxes and Insurance

“There is nothing certain in life but death and taxes.” (Paraphrase Ben Franklin) Inventory costs of taxes and insurance are determined by many factors, including but not limited to; types of product, location, and local ordinances related to product distribution. It is best to consult a lawyer regarding the nuances and costs associated with this category. Alternatively, partnering with a 3PL with extensive experience in your industry can typically provide introductions to legal counsel and help ballpark costings where appropriate.

Inventory Costs Explained – Mistake to Avoid

Understocking

There is nothing worse than missing out on a sale because of stockouts. Proper inventory management systems and tracking can help forecast accurately and avoid losing sales. It is more important to overstock than understock. For one, you miss a sale. Second, you can lose a customer permanently. Third, you have to issue refunds which costs you additional money in employee wages and customer service strain. Include inventory management in product forecasting to help avoid understocking whenever possible.

Failing to Include Inventory Management in Forecasting Sales

The entire process of managing inventory is complicated. Including inventory management in forecasting will improve accuracy and minimize overstock or understock situations. Inventory management data will include product levels, cycles and highlight stock value categories. This helps businesses forecast not based on sales numbers alone but the overall health and movement of products through the inventory management process.

Launching a Product and Retroactively Managing Inventory

Launching the business and then getting around to managing inventory can be tempting. This is a significant mistake because by the time inventory management is a need; it has become a problem. Implementing inventory management before a product launch can help with forecasting, restocking timelines, and reducing stockouts. Accurate sales data, stock levels, and performance are readily available by preparing to track inventory management from the beginning.

Always Buying in Bulk

It is important to buy what you need when you need it. Sometimes bulk purchasing is ideal. Other times, it is a gamble. It might be tempting to buy 1000 units of your most popular product, but it could cost you if that item trends out or becomes obsolete before you can sell them.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, therefore understanding the roll of Third-Party Logistics is integral to keeping up. In light of this our beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

Explaining or managing inventory costs involves a lot of information. Many owners lose sleep over this area of business. Falcon Fulfillment relies on a proprietary inventory management system boasting a 99.9% accuracy rating. We take pride in providing our clients with accurate data, enabling them to make optimal decisions for their businesses.

If you would like to learn more about how Falcon can help streamline your inventory costs, get in touch with one of our agents today.

Let’s Talk!

Shipping Dunnage Types: Ensuring Safe Transit for Your Products

Shipping Dunnage Types: Ensuring Safe Transit for Your Products

Within the logistics systems, an often ignored yet important term emerges – dunnage. This seemingly small element plays a significant role in fulfillment and shipping. Explore the diverse shipping dunnage types, learning its significance, exploring its role as a key element for shippers, and seeing the array of types protecting cargo during its journey from seller to buyer.

What is Dunnage? Shipping Dunnage Types

To the uninitiated, dunnage may seem an obscure term, but to those in the shipping trenches, it’s a familiar and critical ally. At its core, dunnage represents the safety padding materials that play the role of guardians, ensuring the safe travel of goods from point A to B. From the common bubble wrap to the industrial grade solid plastics, dunnage assumes various forms, each with the single mission of securing items in the unpredictable and often hectic environment of transit.

Why Shippers Use Dunnage

Picture this – a package navigating its way through sorting facilities, trucks, ships, and an array of vehicles, subjected to environmental rigors that can test the resilience of even the sturdiest items. This is where dunnage steps into the spotlight, offering a trifecta of benefits that make it an indispensable component of the shipping arsenal.

Damage Protection: Dunnage, often inexpensive, becomes the unsung hero in safeguarding valuable, fragile, and loose items during their turbulent journey.

Moisture Protection: As products traverse diverse climates, the menace of moisture lurks. Dunnage, when wielded right, becomes the shield that protects valuable electronics and sensitive equipment from potential harm.

Shock Absorption: The journey is fraught with challenges – sliding, dropping, squeezing, collisions – and each poses a threat to the integrity of shipped items. Dunnage, strategically placed, transforms into a reliable shock absorber, the last line of defense against the perils of transit.

Shipping Dunnage Types

Understanding the diverse array of materials that can serve as dunnage is crucial for tailoring shipping solutions to the unique needs of various products. Here, we embark on a journey through the common types that form the backbone of secure shipping:

Solid Plastics: Reserved for high-value, industrial shipping, solid plastics emerge as the vanguard against potential damage, albeit at a higher cost.

Bubble Wrap: Versatile, reusable, and a stalwart defender of fragile items, bubble wrap finds its niche as a cushioning agent against impacts.

Wood: Crafting barriers between items, wood becomes the chosen ally for heavy goods that demand a robust shield.

Air Pillows: In the intricate dance of filling gaps and preventing unwanted shifts, air pillows emerge as a practical solution for securing loose spaces in packages.

Kraft Paper: In the realm of cost-effectiveness and eco-friendliness, crinkled kraft paper takes center stage, offering a versatile and reusable option.

Foam: Precision is the name of the game when it comes to padding electronics, medical equipment, and fragile items, making foam a go-to choice for impact protection.

Steel: When the stakes are high, and products tip the scales in weight, steel emerges as a premium option, ensuring the safety of heavier items at an elevated cost.

Corrugated Paper: Marrying technology with functionality, corrugated paper stands as a testament to versatility, moisture protection, and sustainability.

Custom Dunnage Solutions: Uniqueness demands bespoke solutions, and custom dunnage steps in to craft protection tailored to specific dimensions.

Shipping Dunnage Types Pivotal Role in E-Commerce: Safeguarding Shipments and Minimizing Returns

In the expansive domain of freight shippers, dunnage finds relevance within the sphere of e-commerce. Embracing an array of options such as bubble wrap, crinkle paper, air pillows, and recycled paper, the diverse range of dunnage becomes an essential component in delicately averting damage and reducing the likelihood of customer returns.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, understanding the roll of Third-Party Logistics is integral to keeping up. This beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

At Falcon Fulfillment, we offer secure shipping solutions for e-commerce merchants. Our commitment to excellence is evident in our advanced technology, seamless platform integrations, and strategically located fulfillment centers. Moreover, we handle your inventory and orders with care. Particularly for items requiring extra protection, we work closely with merchants to choose dunnage options that ensure safe transit.

Furthermore, in our fulfillment centers, we use recycled crinkle paper to protect fragile items, emphasizing our dedication to sustainable practices. Therefore, for items requiring extra protection, we work closely with merchants to choose dunnage options that ensure safe transit.

Falcon Fulfillment is your reliable partner in the logistics journey, providing security and unmatched service. Your product’s safety is our priority, ensuring a smooth delivery to your customers’ hands.

Let’s Talk!

6 Signs It Is Time to Outsource Fulfillment

6 Signs It Is Time to Outsource Fulfillment

Running a successful e-commerce business is demanding. It requires a lot of time, money, and expertise. Owners are pulled in a thousand directions daily. They manage product development, marketing, order fulfillment, customer service, staffing, and sales, all while remaining focused on future growth opportunities. It’s like running a three-ring circus, only with fewer furry employees. Order fulfillment is a crucial aspect of running a successful e-commerce business. There is a tipping point where order fulfillment can make or break profitability. Here are six signs it might be time to outsource fulfillment.

You Can No Longer Focus on Core Competencies

Focusing on your business’s core competencies has helped you gain success thus far. Continuing to hone and focus on what your company does best will ensure it continues to grow and thrive. There is a business idea that states, “Work on it, not just in it.” Often, a business owner builds the company around their ability to get things done. This works when the business is small but very quickly will bottleneck growth. When your time and attention are being hijacked by order fulfillment more than 20%, you might want to consider outsourcing fulfillment. A 3PL can give you back the headspace you need to refocus on what matters most to you and your customers.

Your Team Cannot Handle the Demand

Orders are rolling in at rates your team is struggling to keep up with. Does this scenario sound familiar? “Everyone is working around the clock to fulfill orders, yet they are getting increasingly delayed. I’m even pulling in admin, sales, and marketing staff to pack and ship product.” You might be laughing, thinking that would never happen to you until your product gets featured on Fixer Upper, or you missed the window to Prepare for Peak. Engaging with a fulfillment company gives you access to an expanded and expert fulfillment team.

You Have Outgrown Your Warehouse Space

It’s challenging to stage receiving and fulfillment when you don’t have the space required to pick, pack, store, and ship products. This is especially difficult when you experience significant fluctuations in order volume. Holiday sales might fill your warehouse capacity and be virtually empty by January. You can utilize flexible warehousing to ebb and flow when you outsource fulfillment.

Order Errors are Increasing

Order errors are apt to happen, but they become more and more common when staff and management are stretched too thin. Whether the mistakes stem from a lack of time, staffing, space, or technology failures, they are costly. A rise in unhappy customers is directly related to order accuracy and promptness. One bad review will cost you 1 in every ten potential customers. For example, if you receive 300 visitors to your online store daily, one lousy review costs you 30 customers per day. Can you afford that loss? 3PL fulfillment teams can provide almost 100% order accuracy, and they can offer fast shipping.

You Know You are Paying Too Much for Shipping

Shipping is expensive. Leveraging every avenue to ensure you get the lowest shipping rates is good business practice. 3PL order fulfillment companies have preferred high-volume discounts with shipping carriers. They pass along those preferred rates to clients. If you are paying the same or more for shipping as your competitors, it might be time to outsource your fulfillment.

You Want to Expand Internationally

Expanding your business to a new country is a huge undertaking. Expert knowledge is helpful whether you are launching in a neighboring country or taking your business worldwide. Fulfillment companies know how to navigate international customs, export and import law, and other complicated areas. They have managed fulfillment for others and can help create and streamline your process to have the most success in your new market.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, therefore understanding the roll of Third-Party Logistics is integral to keeping up. In light of this our beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

Running an e-commerce business is undeniably a 24/7 job. When you find yourself feeling overwhelmed by the sheer number of orders to process and your team is running out of steam, it’s a clear indication that it’s time to outsource fulfillment. By doing so, you’ll gain the invaluable headspace needed to focus on future growth and expansion opportunities. Moreover, partnering with a 3PL fulfillment company like Falcon Fulfillment can provide you with flexible warehouse space, staffing, and cost-effective shipping rates. Consequently, you’ll be well-positioned to ensure that you have the best possible chance of not just surviving, but truly thriving in the face of e-commerce growth.

Talk to one of our agents today to see how we can help you scale.

Let’s Talk!

Top Digital Commerce Skills to Master for E-commerce Success

Building Key Skills for Long-Term Digital Commerce Success

The rapid evolution of digital commerce has dramatically shifted how businesses operate, from product marketing to fulfillment services and beyond. While technology, platforms, and consumer behavior change quickly, one core truth remains — businesses need highly skilled teams to compete and succeed. Mastering digital commerce skills is critical for companies aiming to grow revenue, improve operational efficiency, and stay ahead in an increasingly competitive online landscape.

Let’s break down the essential digital commerce skills modern businesses need, and how they tie into broader operations like third-party logistics (3PL), e-commerce fulfillment, and supply chain management. Focusing on these capabilities will ensure your teams are not only ready for today’s challenges but are also prepared to adapt to future trends.

1. Strategic and Analytical Thinking

At the foundation of digital commerce success lies strategic thinking and data literacy. Without clear strategies, even the best fulfillment services or order fulfillment solutions will struggle to meet customer expectations and drive long-term profitability.

Developing Strategic Mindsets

Digital commerce leaders must hone their ability to analyze data, interpret market trends, and align their strategies with evolving customer demands. This involves skills like:

- Defining omnichannel strategies for multi-channel fulfillment.

- Conducting fulfillment cost analysis to optimize budget allocation.

- Using inventory forecasting to align supply with demand.

Since order fulfillment metrics and reporting provide crucial performance insights, teams need both the tools and analytical know-how to evaluate their performance objectively. Moreover, incorporating inventory tracking software ensures real-time visibility into inventory levels, reducing costly errors.

Data-Driven Decision Making

Data fuels digital commerce strategies. From tracking customer behavior to optimizing shipping and delivery, the ability to analyze data and make informed decisions is invaluable. Businesses should leverage:

- Cloud-based warehouse management systems (WMS) to collect and interpret warehouse data.

- Order tracking and management systems to monitor the full lifecycle of customer orders.

- Transportation management systems (TMS) to analyze and optimize carrier selection and management.

By combining strategic thinking with analytical capabilities, teams can create more resilient operations and improve order accuracy and quality control.

2. Fulfillment and Logistics Expertise

As customer expectations for fast, affordable delivery continue to rise, expertise in warehousing and distribution, last-mile delivery, and cross-docking is no longer optional. These operational digital commerce skills directly impact customer satisfaction and profit margins.

Mastering Fulfillment Operations

Efficient e-commerce fulfillment requires a deep understanding of:

- Vendor-managed inventory (VMI) for improved supply chain efficiency.

- Reverse logistics for seamless returns processing.

- Kitting and assembly to enhance order customization and value.

- Bulk shipping strategies to minimize per-unit shipping costs.

Digital commerce teams must also understand packaging optimization to balance protection and cost, particularly for international shipping and import/export orders. These digital commerce skills enable businesses to compete on both price and service.

Seamless Integration with Fulfillment Partners

Since many brands rely on third-party logistics (3PL) providers to handle fulfillment at scale, businesses need to develop expertise in 3PL technology solutions. Understanding how to leverage fulfillment centers and freight consolidation helps companies maximize efficiency while maintaining visibility into inventory and order status.

Collaborating with a 3PL also requires familiarity with:

- Customs brokerage for cross-border shipments.

- Freight rate negotiation to secure competitive rates.

- Freight audit and payment services to validate transportation costs.

These operational digital commerce skills ensure smoother collaboration between internal teams and external partners, ultimately driving better fulfillment outcomes.

3. Future-Focused Skills for Long-Term Growth

To stay competitive, businesses need to develop skills that go beyond the basics. These future-focused digital commerce skills will ensure your teams remain agile and innovative as the industry evolves.

Enhancing Customer-Centric Capabilities

Customers now expect hyper-personalized, seamless experiences across all channels. This requires developing skills like:

- Personalization strategy development.

- E-commerce integration services expertise to connect platforms.

- Expertise in order splitting and routing to optimize multi-warehouse fulfillment.

Customer satisfaction also hinges on delivery speed and transparency. That’s why teams must develop expertise in:

- Same-day and next-day delivery coordination.

- Real-time order tracking and management for improved communication.

Leveraging Automation and Technology

Automation is increasingly crucial to driving efficiency in digital commerce skills development. Skills related to warehouse automation, inventory cycle counts, and demand planning allow companies to work smarter, not harder. These skills reduce reliance on manual processes while improving accuracy and speed.

Additionally, a forward-thinking team should understand:

- Scalable fulfillment solutions for growth-stage flexibility.

- Advanced use of order fulfillment metrics and reporting to identify operational gaps.

- Emerging tech trends like AI-driven inventory forecasting.

Bringing It All Together

Ultimately, success in digital commerce relies on blending strategic, operational, and forward-looking skills into a cohesive workforce strategy. By investing in digital commerce skills development, businesses enhance their ability to adapt to change, meet customer expectations, and achieve sustained growth.

Moreover, effective skill-building doesn’t happen in isolation. Strong collaboration between marketing, logistics, and fulfillment teams ensures that third-party logistics (3PL) partnerships, fulfillment services, and internal capabilities align to create seamless customer experiences.

Continuous Skill Development

Because digital commerce will only grow more complex, ongoing training and development programs are essential. Whether it’s mastering inventory tracking software or understanding the nuances of reverse logistics, every new skill adds resilience and flexibility to your operations.

In conclusion, companies that prioritize building digital commerce skills—spanning strategic planning, fulfillment operations, and future-readiness—are better positioned to thrive in today’s fast-paced e-commerce environment. Combining these skills with strong fulfillment and supply chain optimization practices creates a foundation for sustained success.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, understanding the roll of Third-Party Logistics is integral to keeping up. This beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

With economic uncertainty becoming normal, developing digital commerce skills across strategy, fulfillment operations, and technology adoption represents a competitive imperative. Regularly distilling insights from evolving consumer expectations — including demands for faster delivery, real-time visibility, and seamless returns — will provide directional validation. Ultimately, brands that invest in workforce development alongside third-party logistics (3PL) and fulfillment partners who share their commitment to efficiency and quality will build hard-won consumer trust through reputations for reliability and innovation.

Reach out to Falcon Fulfillment for help building a supply chain supported by skilled teams and quality partners.

Let’s Talk!

Quality Control in Supplement Manufacturing With the Right Partner

Quality Control in Supplement Manufacturing: Choosing the Right Partner

As economic instability leads supplement consumers to intensely evaluate purchases, brands must align with contract manufacturers boasting ironclad quality control in supplement manufacturing. Per data from market research firm NEXT, over 50% of consumers maintain strong values convictions, “willing to pay more for ethically and responsibly-made products.” However, with ongoing supply chain turmoil ratcheting up costs, consumers also demand affordability and value. Contract manufacturers excelling at stringent quality assurance (QA) and quality control (QC) protocols allow brands to deliver premium quality without sacrificing accessibility.

Rigorously Vetting QA/QC Protocols

Validating contract manufacturers on quality measures begins with reviewing both external and internal benchmarks. Externally, certifications from respected third-party auditors like NSF International, UL-STR, and the Natural Products Association validate foundational best practices. As FDA regulatory scrutiny accelerates across the supplement industry, checking for spotless facility inspection records and no serious 483 observations or warning letters gives added confidence in quality infrastructure.

Internally, key performance indicators (KPIs) reveal more granular adherence to standards. Brands must scrutinize order fulfillment accuracy rates, inventory cycle counting precision before shipments, first pass quality yield percentages, recall readiness drill success rates, and more. By regularly monitoring such manufacturing, warehousing and distribution metrics, brands ascertain whether technologies, automated equipment, and cloud-based platforms effectively support standardized quality control end-to-end.

Sustainability Commitments Uphold Brand Reputation

In supplier selection processes today, quality assurance capabilities cannot be divorced from ecological values. Per Packaging Digest research, over 80% of consumers now review sustainability claims before purchases. Moreover, over 50% of boomers and millennials confirm they are willing to pay more for responsibly-sourced components, eco-friendly manufacturing practices and minimalist packaging reflecting corporate commitments to Circular Economy principles. Contract manufacturers like Soft Gel Technologies advancing solvent recycling technology, water recovery systems and innovative low waste packaging design align with both emerging regulations and consumer preferences – keeping brands a step ahead.

Vetting Supply Chain and Logistics Experience

In choosing a manufacturing partner equipped for growth amid economic uncertainty, Soft Gel CFO Hiroshi Kishimoto explains, “pay close attention to the quality unit and how decision-making around standards is implemented for consistency across multiple facilities.” Whether addressing demand surges or materials shortages, the most resilient contract manufacturers proactively invest in digitized ecosystems providing end-to-end supply chain visibility – the foundational data layer informing agile responses using predictive analytics.

Seasoned partners constantly refine core safety protocols, upgrade automated controls and traceability infrastructure, install the latest high-precision equipment, implement cybersecurity controls and refine business continuity programs. Continually evaluating potential failure points through rigorous quality risk assessments. This fixation on incrementally identifying and closing process vulnerabilities before finished products are impacted spurs continuous improvement imperative for establishing trust with scrutinizing consumers.

Cultivating an End-to-End Culture of Quality

To deliver finished supplements warranting premium price tags, a commitment to quality must permeate every link in the supply chain. Firstly, standards for carriers, freight handlers and 3PL partners should mandate real-time shipment tracking across legible chain-of-custody documentation. Additionally, formal contracts outline acceptable facility audit scheduling and codify compliance with published quality guidelines. Without diligent vetting and training reinforcement of outsourced production, packaging, transportation and logistics teams, preventable errors risk compromising integrity-driven brands. Finally, proactive relationship management procedures and open communication channels allow manufacturers to swiftly address any emerging component, raw material or packaging quality issues observed.

Proactive relationship management procedures and open communication channels allow manufacturers to swiftly address any emerging component, raw material or packaging quality issues observed. Moreover, integrating supply chain management best practices with steadfast quality culture builds reputations and consumer loyalty that withstand the test of time. Overall, by combining proactive vendor relationships with integration of quality across supply chain partners, manufacturers can foster enduring bonds of trust with end consumers that are unaffected by temporary market turbulence.

Key Takeaways on Quality Control in Supplement Manufacturing

As scrutiny of supplement purchases further intensifies into 2023, integrity-focused brands should align with contract manufacturing partners delivering:

- Independently-certified QA/QC protocols confirming cGMP rigor

- Supply chain transparency established through blockchain or other track and trace analytics

- Proven expertise traversing volatile market environments through clarity at scale

- Environmental stewardship transcending what regulations mandate

- Future-proofed supply chain agility preventing disruptions

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, understanding the roll of Third-Party Logistics is integral to keeping up. This beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

With economic uncertainty becoming normal, choosing manufacturing collaborators dedicated to improvement through orchestration and technology adoption represents a competitive imperative. Regularly distilling insights from shifting consumer expectations – and even skepticism – will provide directional validation. Ultimately, brands co-investing alongside partners sharing their quality commitment will earn hard-won consumer trust through reputations for consistency and accountability.

Reach out to Falcon Fulfillment for help finding quality partners for your supply chain.

Let’s Talk!

4 Ways to Maximize Your 3PL Partnership

Maximize Your Partnership With Your 3PL

E-commerce brands today rely heavily on Third-Party Logistics (3PL) providers for scalable order fulfillment solutions. As your operations grow, choosing the right 3PL partner is critical for success.

A maximized 3PL partnership allows you to tap into the 3PL’s expertise in fulfillment services, warehousing and distribution, inventory management, and supply chain optimization. This lifts a heavy operational burden so you can focus on sales and marketing.

But how exactly can you maximize the 3PL partnership for peak performance? Here are 4 key ways:

1. Align Goals and Create Transparency

Getting alignment on goals, expectations and processes is crucial upfront. Prioritize open communication channels right from the start.

Provide visibility into your sales forecasts, inventory needs, and growth projections. In return, get clarity on the 3PL’s fulfillment capabilities, warehouse locations, automation and technology infrastructure.

Setting defined SLAs (service level agreements) and KPIs for order accuracy, on-time delivery, and inventory accuracy also creates accountability on both sides.

Ongoing transparency through fulfillment metrics and reporting ensures potential gaps are addressed proactively before they impact customers. This allows for scalable and flexible solutions as needed.

2. Leverage the 3PL’s Technology Capabilities

Advanced 3PL partners offer e-commerce brands far more than just bricks-and-mortar warehousing and shipping services today. Technology is a key component to consider when maximizing your 3PL partnership.

Look for providers that offer integrated inventory management platforms, Cloud-Based WMS, shipment consolidation tools, TMS integration and more.

The right technology stack gives you end-to-end visibility and timely insights to optimize inventory planning, demand forecasting, and omnichannel order orchestration across channels.

Automated inventory tracking and order management also minimize overhead while enabling faster fulfillment, fewer backorders and higher product availability.

This is especially valuable for e-commerce brands selling across multiple online stores, marketplaces and retail channels.

3. Treat the 3PL Like an Extension of Your Team

Think of a maximized 3PL partnership as essentially adding a fulfillment and supply chain management extension to your internal team.

Tap into their expertise through regular check-ins and strategy sessions. Seek input on inventory optimization, freight cost management, custom kitting solutions, daily order orchestration and more.

This approach allows you to benefit from capabilities and experience that are too expensive to build in-house during early growth stages.

You also gain flexibility to meet seasonal or unexpected order peaks seamlessly without lengthy talent acquisition and training. Enable your team to focus intensely on sales, marketing and product development instead.

4. Prioritize Agility and Continuous Improvement to Help Maximize 3PL Partnerships

Even with alignment and robust processes in place initially, brands and 3PLs must collaboratively adapt to evolving needs.

As you grow, fulfillment requirements may change needing solutions like white glove services, custom kitting, or a West Coast warehouse for faster nationwide delivery.

Be ready to add or modify services, integrate new technology, improve workflows and more. Keep an eye on fulfillment KPIs together and leverage root cause analysis for continuous improvement.

Also anticipate and collaborate on capacity planning for big sales events or new product launches. Quickly activating overflow supports and contingency plans prevents chaotic catch-up during peak seasons.

The Perfect 3PL Partner Powers E-commerce Growth

While this covers four major areas of focus, maximizing your 3PL simply requires seeing them as an integral strategic partner rather than just a vendor.

Approaching engagement with collaboration, transparency and leveraging their supply chain expertise at every step sets you up for optimized success as partners.

Beginner’s Guide to Third-Party Logistics (3PL)

The world of e-commerce is always changing, therefore understanding the roll of Third-Party Logistics is integral to keeping up. In light of this our beginner’s guide to third-party logistics (3PL) will delve into the essential aspects, offering insights into fulfillment services, warehousing, and much more.

Read More…

The right 3PL ally allows your lean e-commerce team to effectively compete at enterprise levels when it comes to world-class order fulfillment. This accelerates profitable omnichannel growth so you can better serve customers with supply chain excellence.

Does your brand need scalable fulfillment solutions to achieve ambitious omnichannel commerce goals? Reach out to discuss your needs and we’ll provide solutions tailored to your unique requirements.

Let’s Talk!